Washing facilities

LCT washing facilities –

Efficient cleaning solutions for the highest demands

If you are looking for an efficient solution for cleaning and maintaining your production equipment, then LCT washing facilities is the right choice for you. But what makes an LCT washing facilities so special?

An LCT washing facilities is more than just a cleaning device. It is a powerful tool that not only cleans and degreases, but also preserves and phosphates. Whether you need a single-stage or multi-stage solution – at LCT you will find the right model for your specific production process.

The LCT washing systems are designed to fit seamlessly into your production process. They are flexible and can be adapted depending on how your downstream production process goes. This means you get exactly the cleaning and maintenance service you need to ensure smooth operation.

In summary, an LCT washer provides an efficient and effective solution to your cleaning needs. With their wide range of services – from cleaning and degreasing to preservation and phosphating – you can be sure that your production equipment remains in top condition.

Take advantage of the benefits offered by an LCT washing system and improve the efficiency and quality of your production process. Contact us today and let’s find the perfect solution for your needs together.

LCT models

Washing facilities

Round basket washer

Front loader cleaning systems

Continuous cleaning systems

Combination washing systems

Cleaning systems for engine blocks

Drum cleaning system Small parts

Continuous cleaning systems for containers

Rotary cleaning systems

Construction of special washing plants

Mobile work trolley with basket

Mobile work trolley with basket

Mobile work trolley with basket

Mobile work trolley with basket

Mobile work trolley with basket

Vacuum dryer for return conveyor belts

Vacuum dryer for return conveyor belts

Vacuum dryer for return conveyor belts

Vacuum dryer for return conveyor belts

Cleaning system for cylindrical parts

Hydraulic cylinder tub cleaning machine

Mobile work trolley with basket

Mobile work trolley with basket

Mobile work trolley with basket

Mobile work trolley with basket

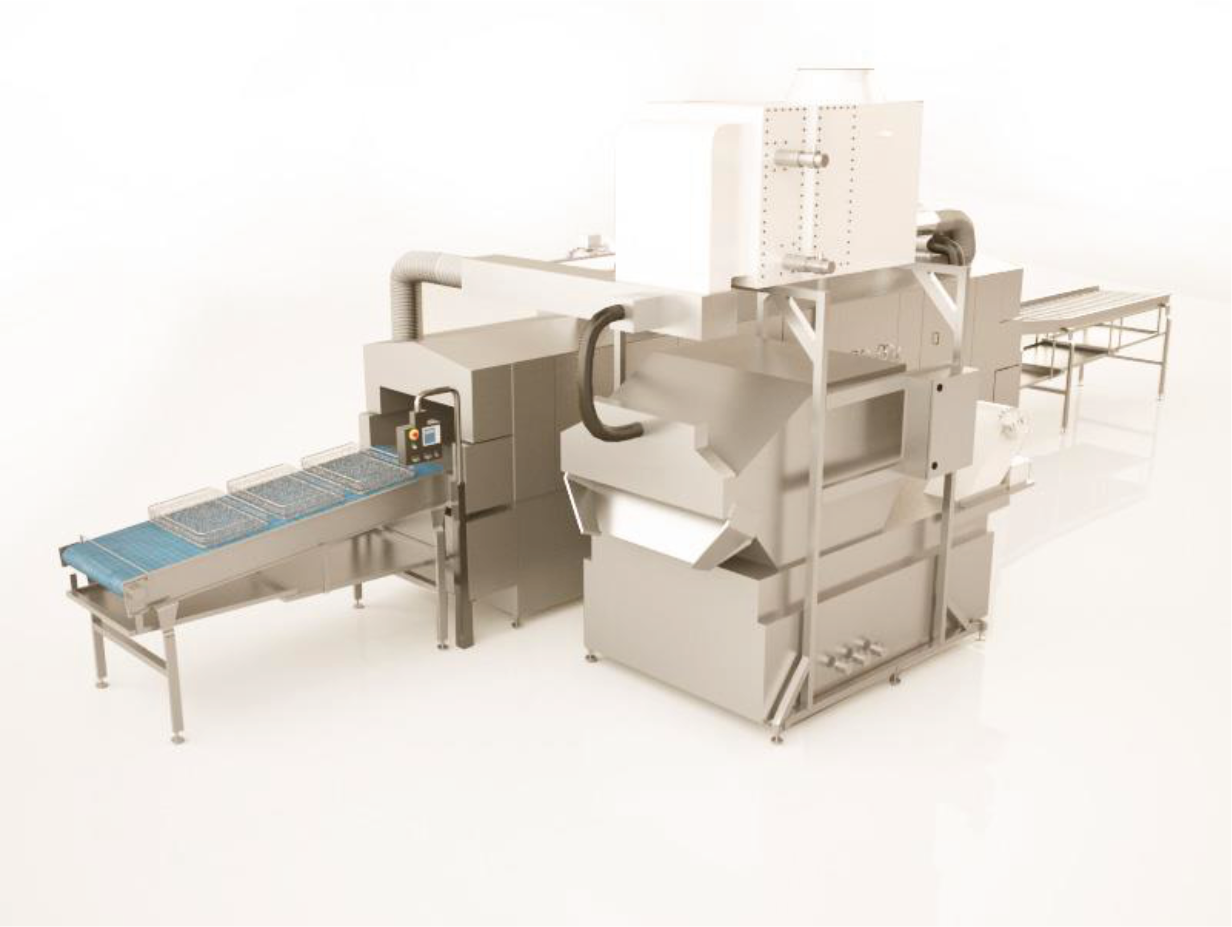

Pass-through Machine for washing

and blowing of small components

Vacuum dryer for return conveyor belts

Vacuum dryer for return conveyor belts

Vacuum dryer for return conveyor belts

Washing machine for small components

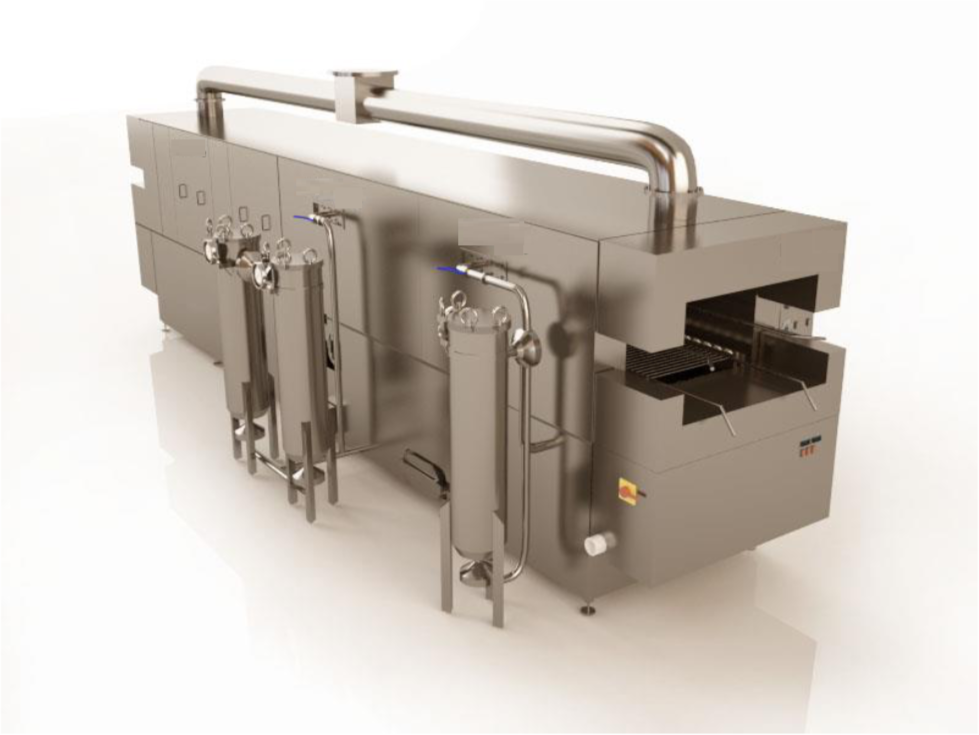

Continuous washing

system for LCT crates

Mobile work trolley with basket

Mobile work trolley with basket

Mobile work trolley with basket

Vacuum dryer for return conveyor belts

Vacuum dryer for return conveyor belts

Vacuum dryer for return conveyor belts

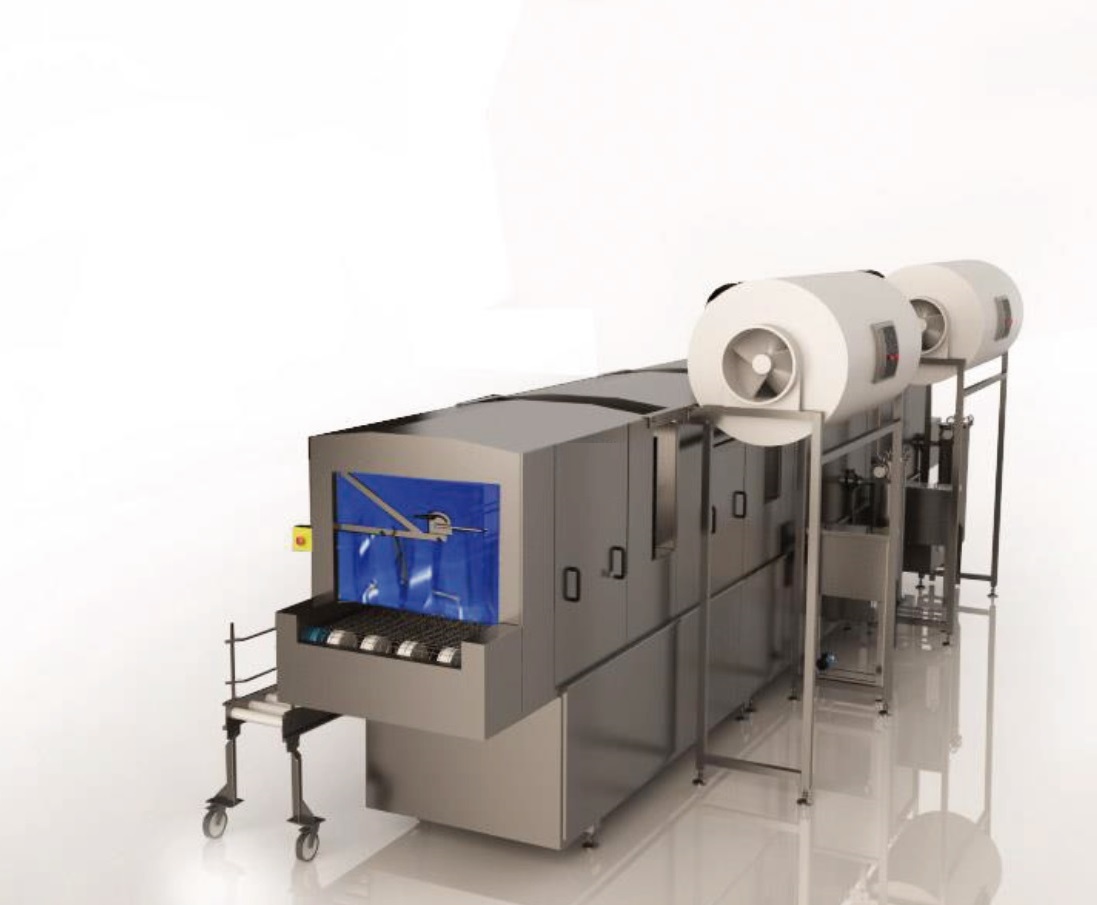

Continuous washing system for LCT crates

This continuous washing system ensures professional cleaning of metal and plastic chips, oil and

lubricant residues from LCT crates in the automotive industry.

The machine has five zones – main washing zone, rinsing zone and three blow-off zones.

The water in the tanks is continuously filtered by two oil separators, one for each tank. Steam extraction

fans capture the vapors produced during the washing and rinsing process and return them to the

machine as hot condensate. This makes crate washing very resource-efficient.

The machine is equipped with two bag filters (one per zone) that capture particles down to 100 μm.

In the blow-off zones, the washed crates and molds are blown dry with a combination of 5 fans,

removing any residual water.

The last blow-off zone is equipped with a hot air blower that effectively dries the crates.

The transport speed can be adjusted via a frequency converter depending on the degree of

contamination.

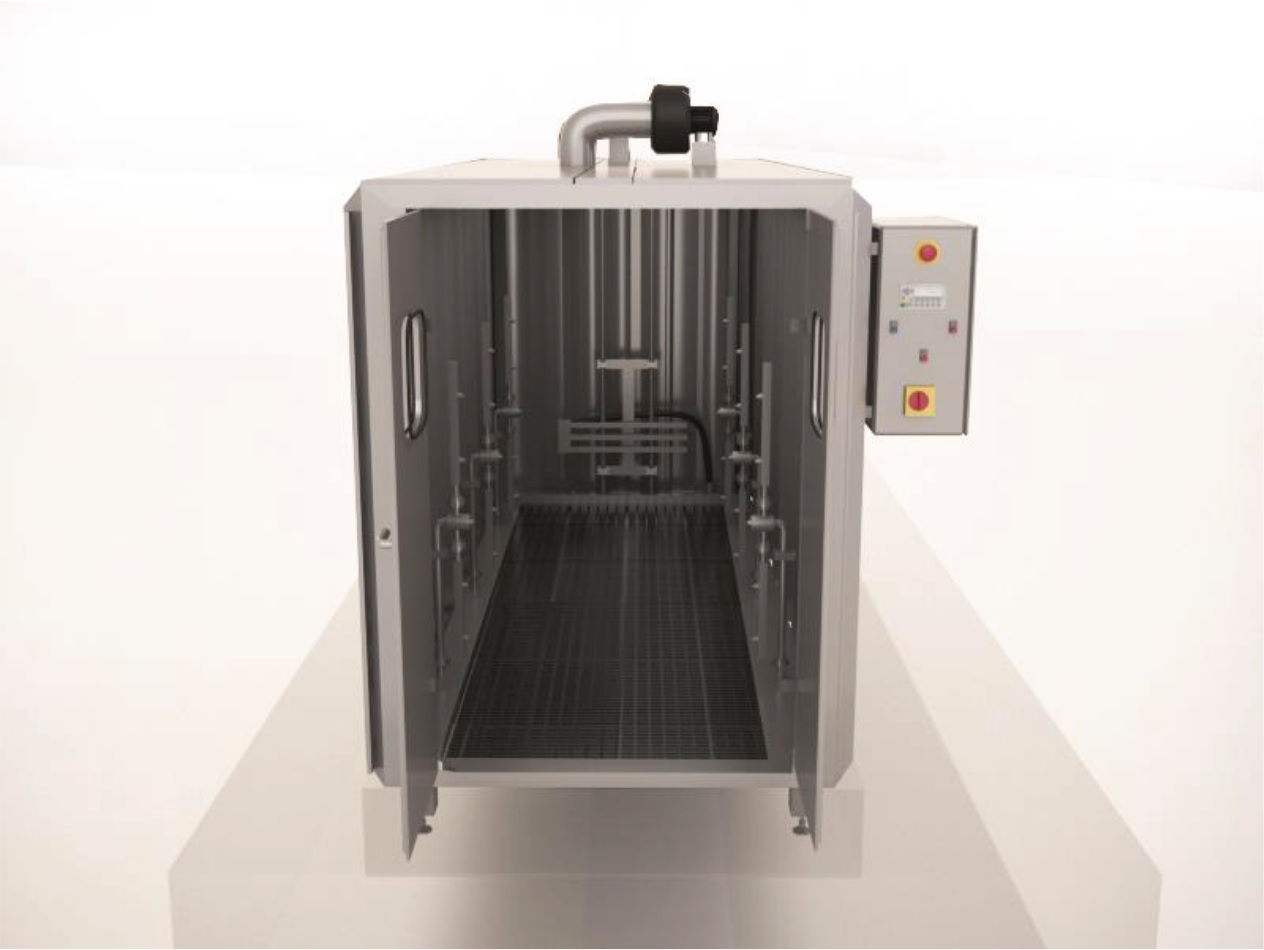

Pass-through Machine for washing and blowing of small components

The machine is designed for cleaning, degreasing, chemical treatment of the outer layer and blowing of small

components. The parts are arranged in trays with dimensions 600 x 400 x 70-150 mm.

Two washing zones – pre-washing zone and zone for mainly washing. After each washing zone there is zone for

blowing. The pre-washing zone has an external band filter, which is with the possibility of processing a high

volume of washing solution and captures particles of a size greater than 350 μm. The band filter cleaning the

washing solution of oil and hard dirt. The mainly washing zone has a column bag filter, which captures particles

of a size greater than 50 μ m. Both filters have monitoring systems for the degree of soiling and incase of

clogging the machine stops. Automatic dosing of the cleaning agent.

Washing Machine for small components

For cleaning, degreasing, rinsing and drying of small parts placed in plastic box 600x400x150 mm.

Electrical heating, steam heating is an option. Automatic dosing pump for adding detergent.

Hydraulic cylinder tube cleaning machine

The machine is developed for effective and economical cleaning and degreasing of cylinder tubes in manufacturing plants.

The front loader works with water-based cleaning agents up to 70°C operating temperature and cleans cylinder tubes from the inside and

outside using a specially developed nozzle system and a powerful centrifugal pump. The dimensions of the cylinder tubes to be cleaned can vary

from a length of 500 to 3100 mm and a diameter of 25 to 90 mm. Up to 7 pipes can be washed at the same time in one batch. The cylinder tubes

to be washed are positioned horizontally on a special receiving platform with a degree of inclination and are automatically moved in and out of

the machine. The machine has 2 cleaning regimes: internal washing and external washing of the cylinder tubes. The equipment includes 2 bag

filters with stainless-steel housings, a highly effective stainless-steel plate phase separator for separating the oil, steam vapor extraction fan, PLC

Siemens 1200 and user-friendly control via 7″ Siemens display touchscreen.

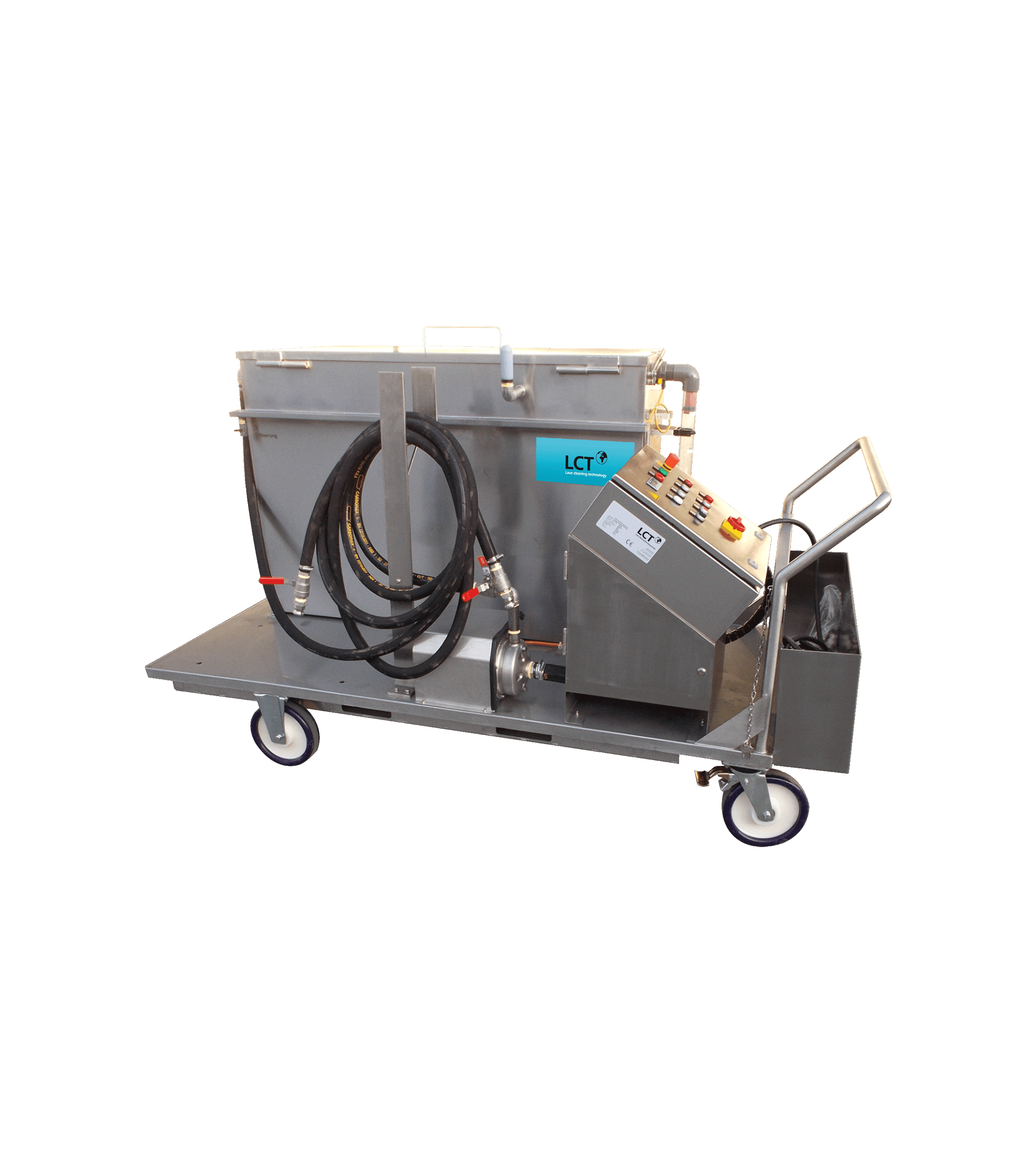

RWR cleaning systems

Deposits in pipes, heat exchangers, coolers, cooling ducts or other systems can lead to operating faults or production downtimes. The solution is regular cleaning of the systems with the RWR pipe and heat exchanger cleaning system. The RWR, which is made entirely of stainless steel, cleans and rinses the systems on the basis of recirculation flushing: this saves time and money, as there is no need for time-consuming assembly and disassembly work. Even complicated pipe geometries can be cleaned quickly and effectively.

We have designed different plants for the various requirements for optimal removal of deposits from the systems: All systems are mobile (stainless steel trolley), robust and equipped with many technical details.

Round basket washers

The basic series of our “Stainless steel cleaning technology” series are: – W for hot/water cleaning – K for cold cleaning

The basic series of our “Stainless steel cleaning technology” series are: – W for hot/water cleaning – K for cold cleaning

Special features:

- Cleaning of a wide range of materials

- Repair

- Repair

- New parts production

- Relaxation

- Compact design, easy handling

- High cleaning power

- Energy-efficient and cost-effective

Front loader cleaning systems

Variant of the basic series for large interior heights with vertical door opening, undercarriage, trolley or roller conveyors

Continuous cleaning systems

- Continuous flow systems for very large quantities

- Conveyor belts as required to match the system

- Automatic feeding and acceptance by robot possible

- Vacuum drying on request

- Each system is specially designed for the material to be washed

- Various conveyor belts for special wash goods and surfaces

Combination cleaning systems for automatic and manual cleaning

- Lid with viewing window, lighting and gauntlets

-

Pump for hand gun approx. 3 – 6 bar with high litre capacity (e.g. for pressure flushing of oil lines and oil ducts in crankshafts or engine blocks).

-

Washing brush, medium flow

-

Compressed air blow-off gun

-

High-pressure gun with connection for an external high-pressure unit (additional water input into the wash bath)

-

optional: integrated high-pressure pump 100 bar or 160 bar for removing even the most stubborn dirt (e.g. oil carbon) – recirculation of the wash bath.

Cleaning systems for engine blocks

The machine is designed for quick and easy cleaning and degreasing of engine blocks, gearbox housings and other machine parts. The size of the engine block can be up to 2500 x 950 x 800 mm and the load max. 2500 kg. The parts are placed on a mobile table that is positioned in front of the machine. A mechanical connection guides the table’s panel inwards. The parts are washed with the help of three nozzle collectors – two stationary and one mobile. The machine has a dirt and oil separator. The dirt separator removes coarse dirt, larger than Ø 1.5mm. The belt oil separator separates the oil from the cleaning agent.

Drum cleaning systems for cleaning small parts

The units of the TH series are designed for cleaning sensitive wash goods. Cleaning inside the small parts baskets, which are inserted into a turning device, can prevent damage.

For parts with complicated surfaces that have to be turned due to their structure, this results in optimal cleaning.

Within this series, customised pick-up devices, basket systems and insert baskets with mesh sizes up to 1 mm can also be integrated.

The feeding of the plants takes place via a mobile work trolley or via roller conveyor systems.

All units of this series can be operated in the hot/aqueous range (W) and in a special version also with cold cleaning agents or solvents (K) or with indirect bath heating for the use of a mixture of 20% hydrocarbon and 80% water.

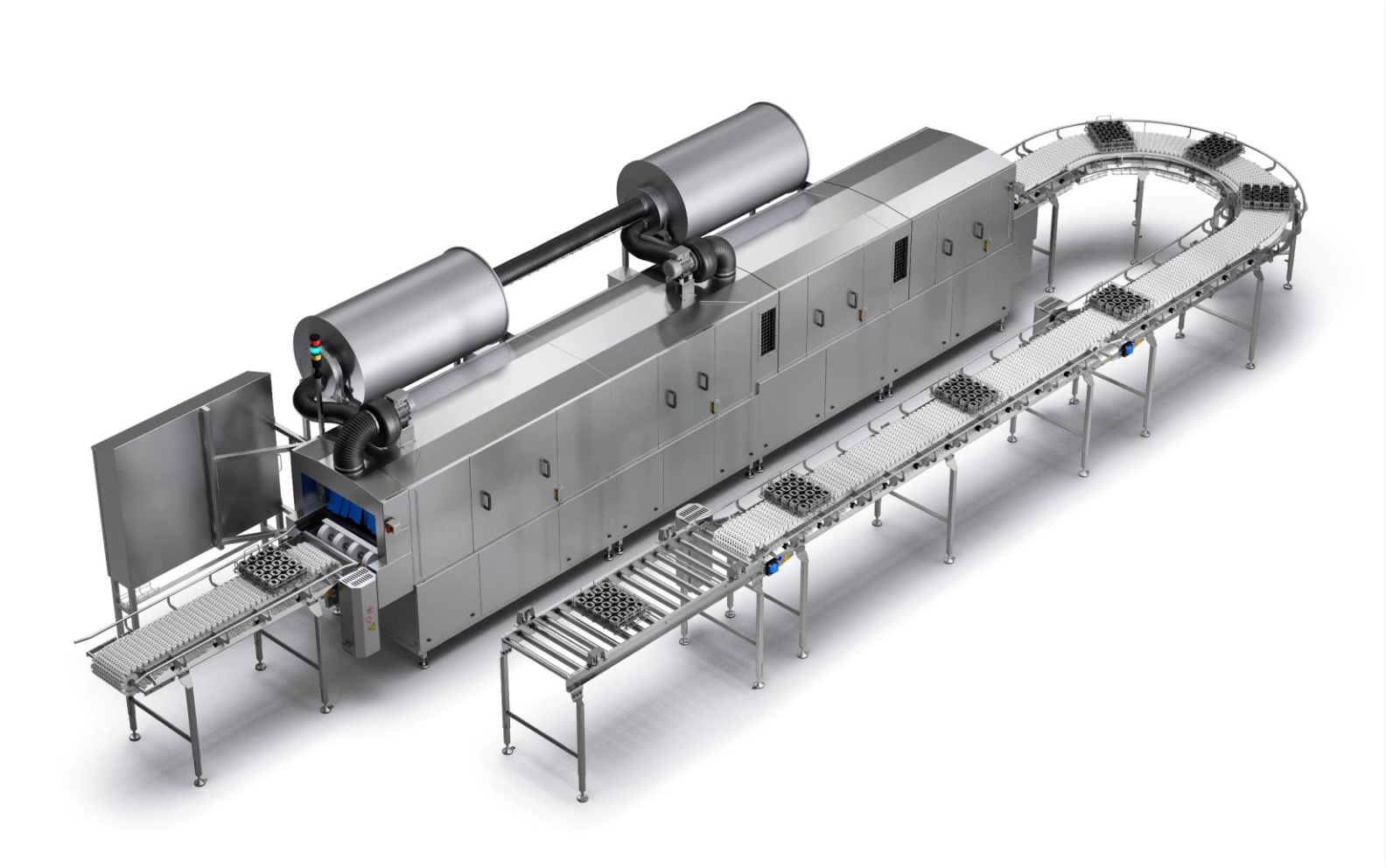

Continuous cleaning systems for LCT containers and parts carriers

Designed for quick, easy and effective cleaning of LCT containers in the automotive industry. The machine has three zones – main wash zone, rinse zone and blow-off zone, equipped with two tanks. The circulating water is permanently filtered through two oil separators, one for each tank.

Construction of special washing plants

- Construction according to specification of the parts to be cleaned

- Can be realised according to customer requirements

- Integration into existing production plants

- Tests are carried out beforehand in our technical centre

- Also possible underground

Mobile work trolley with pull-out basket

Mobile work trolley with pull-out basket is used for batchwise loading of the cleaning system and enables flexible, location-independent loading of the wash basket outside the machine at different areas of the operation.

Rotary cleaning systems for large bulk material parts

The LCT rotary cleaning system is designed, on the one hand, for the batchwise cleaning of small parts, pipes and bulk material in Euro grid boxes and, on the other hand, for holding the heaviest parts, e.g. engine blocks, which are rotated and/or swivelled during the washing process.

Vacuum dryer for return conveyor belts

The installation is designed for fast and effective vacuum drying of parts in metal boxes. The crates are automatically fed to the vacuum chamber on a roller conveyor in two groups standing one above the other.

Cleaning system for cylindrical parts

Designed for cleaning and degreasing cylindrical parts. The parts are placed on a trolley and positioned in the chamber of the machine. Parts are cleaned by seven nozzle collectors – six rotating and one that moves up and down.

To the LCT online shop

Our product range contains a large number of high-quality products for a wide variety of requirements.

Request information

Feel free to request further information on specific topics by e-mail!

Trial requests

We would be happy to visit you on site with our LCT mobile on wheels to give you a practical demonstration of our products..

You are welcome to send us your soiled or residue-laden production parts and we will find the right cleaner or cleaning process for your application.

In our technical centre, we can simulate all application processes, from simple dipping to spraying to ultrasound or high-pressure processes.

Contact us at any time!

Please fill in the adjacent fields or call us.

E-mail address

info@laue-cleaning-technology.de

Phone | Fax

+49 (0) 5 71 / 38 60 14 99

+49 (0) 5 71 / 38 61 05 05

Address

Lindenstraße 31

DE- 32457 Porta Westfalica

Request further information

Please send me further information by e-mail on the following topics: