Used plants

REFURBISHED MACHINES

To conserve our earth’s resources, we also offer you equipment taken in part exchange by our customers which is no longer needed for their processes.

These refurbished systems have been completely technically overhauled by us and can thus achieve significant savings for your operation and thus continue to provide their service for years to come.

Used plants

Selection

Franke drum washing system

Ultrasonic cleaning tank type NW 180

Parts washing system HTW 1200

Parts washing system HTW 1500

Parts washing system HTW 1000

Parts washing system HTW 800

Laborex two-chamber parts cleaning system

Parts washing system HTW 1500

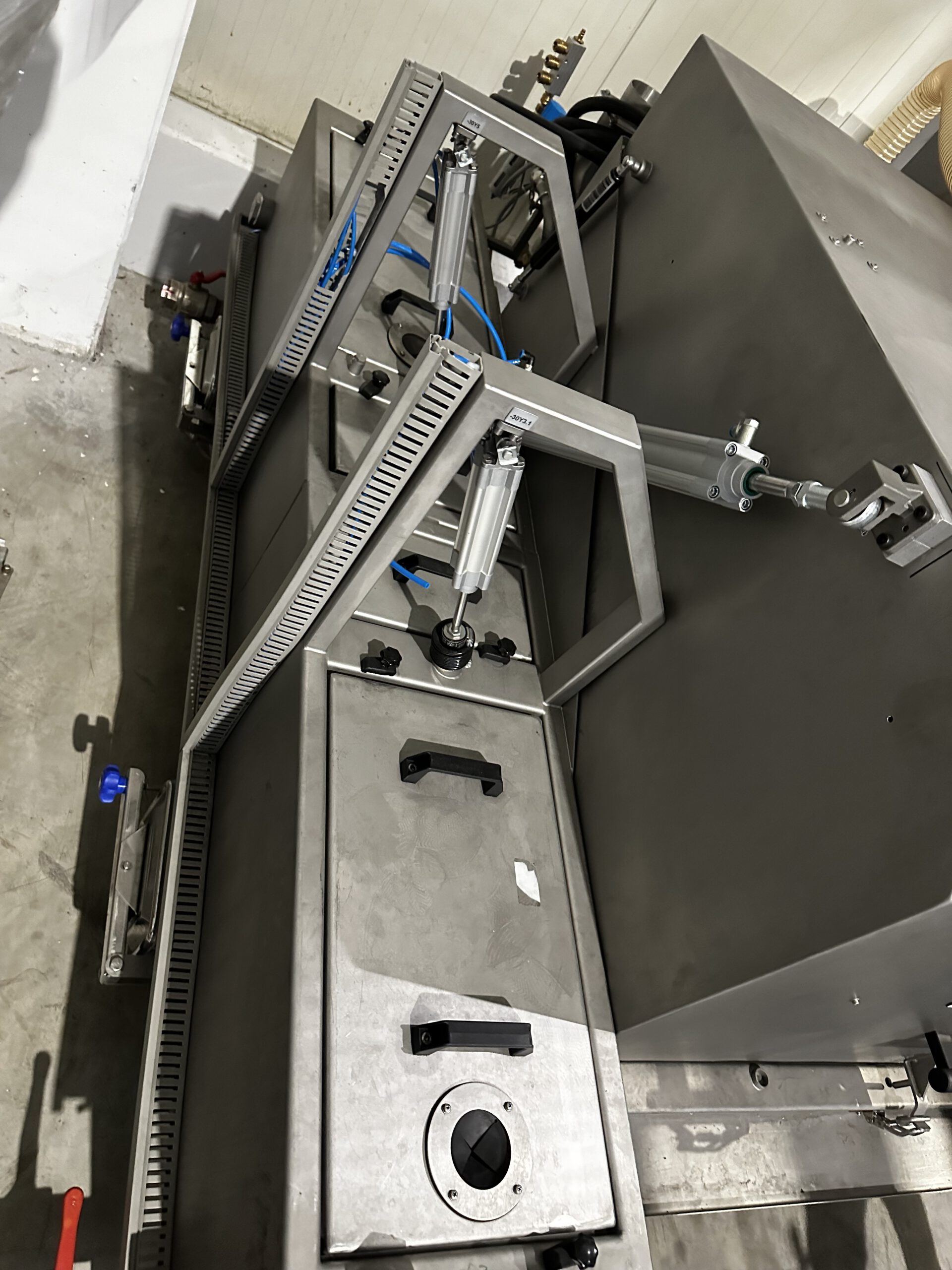

Continuous washing system

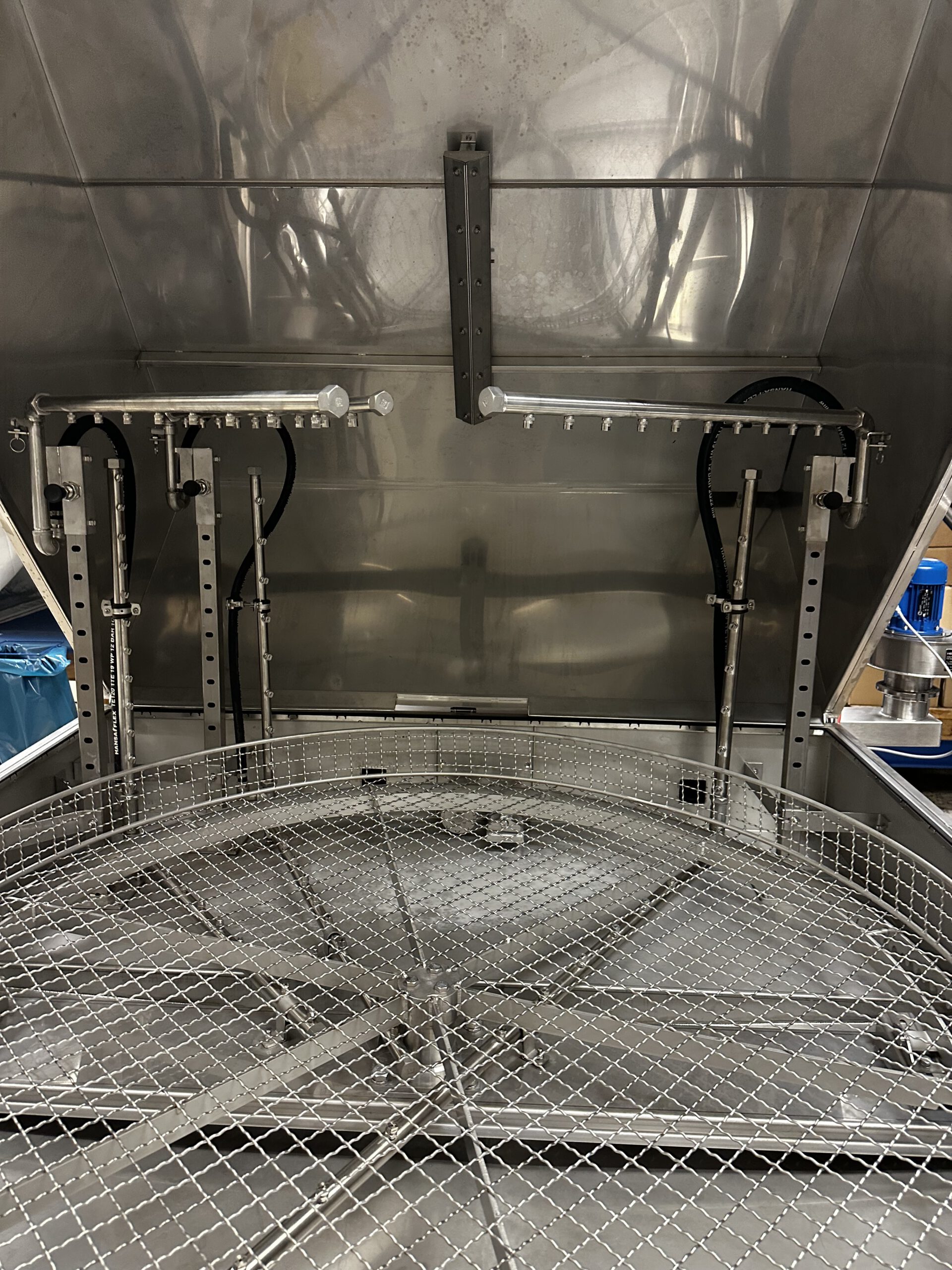

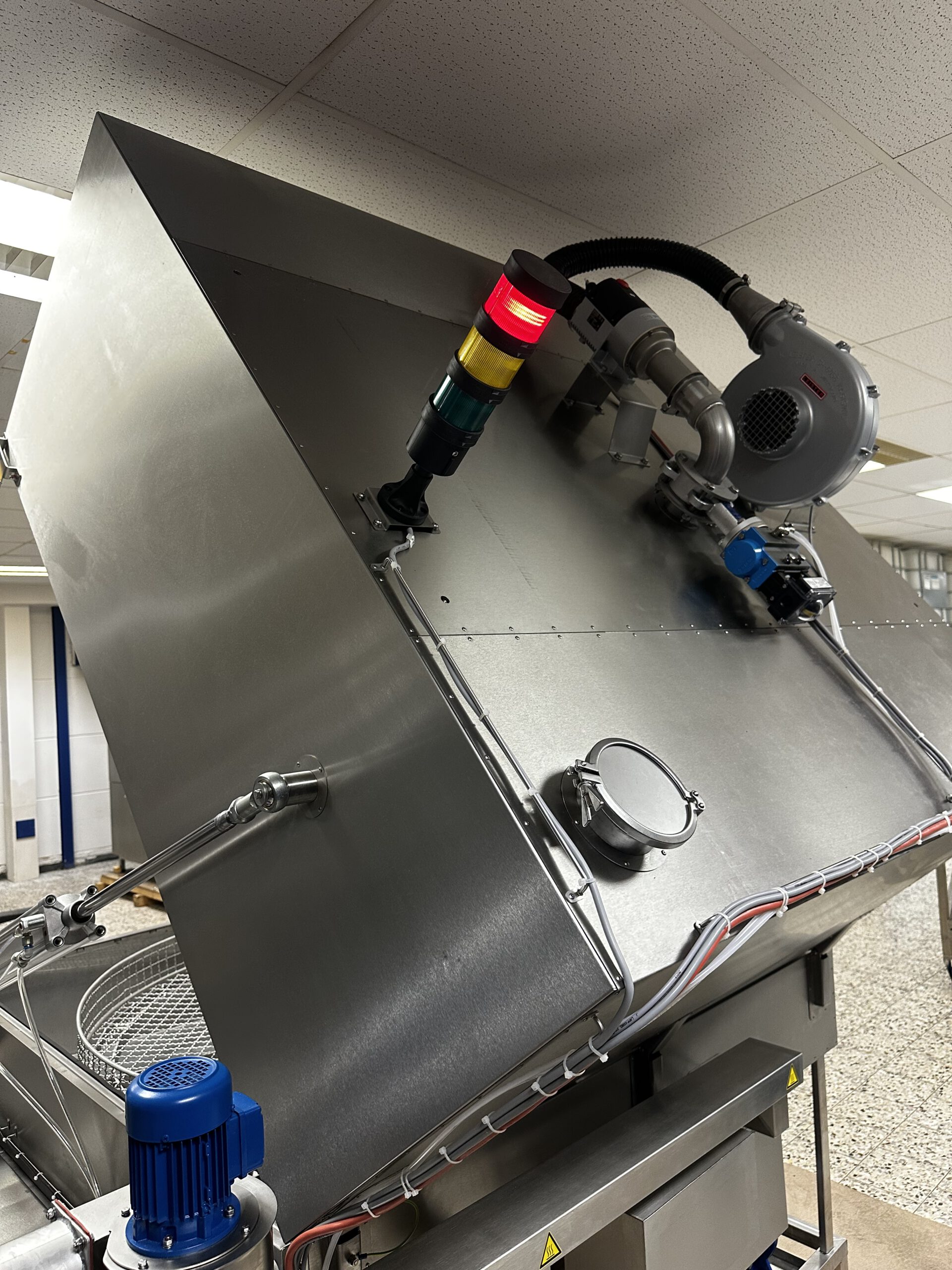

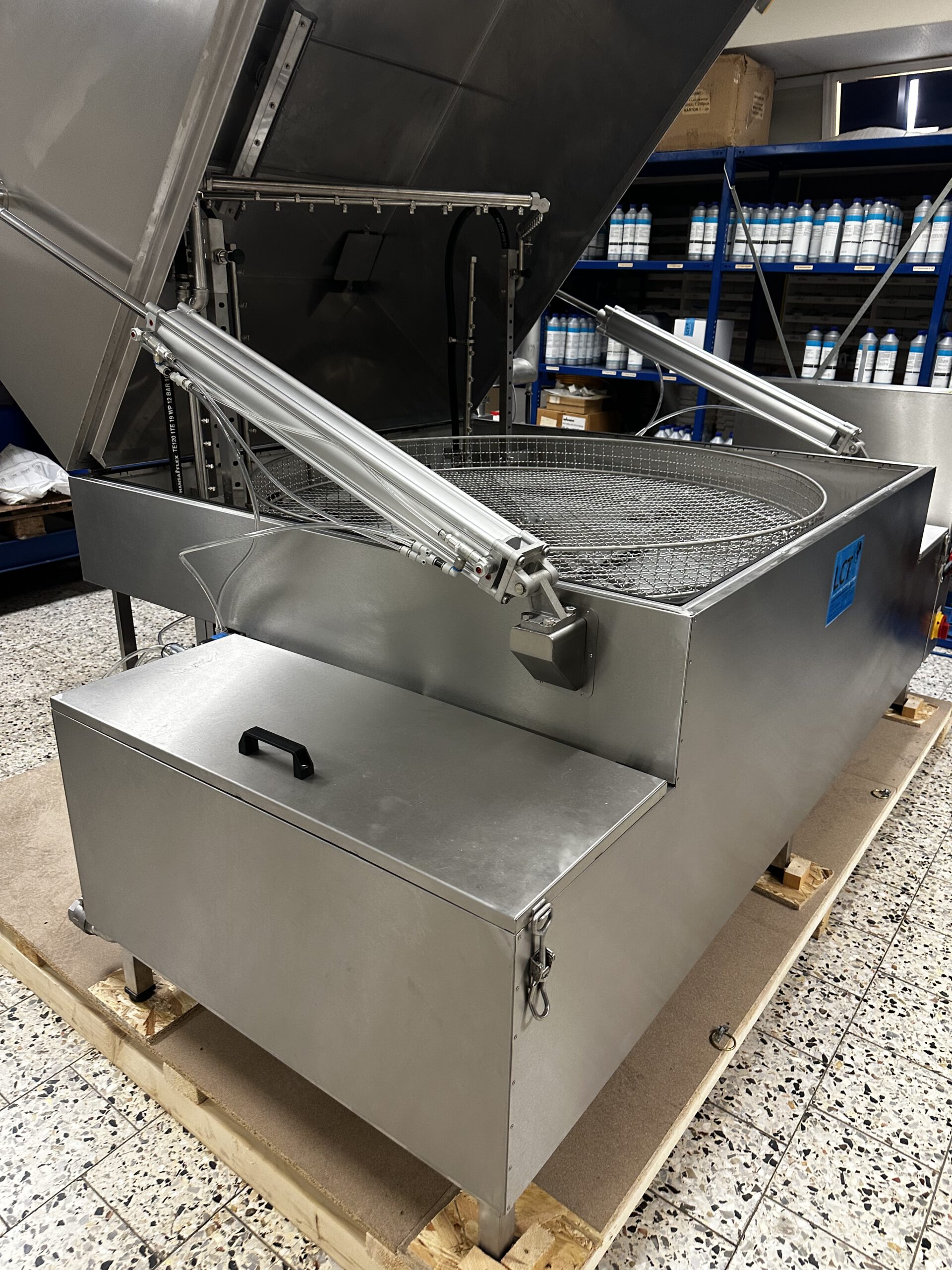

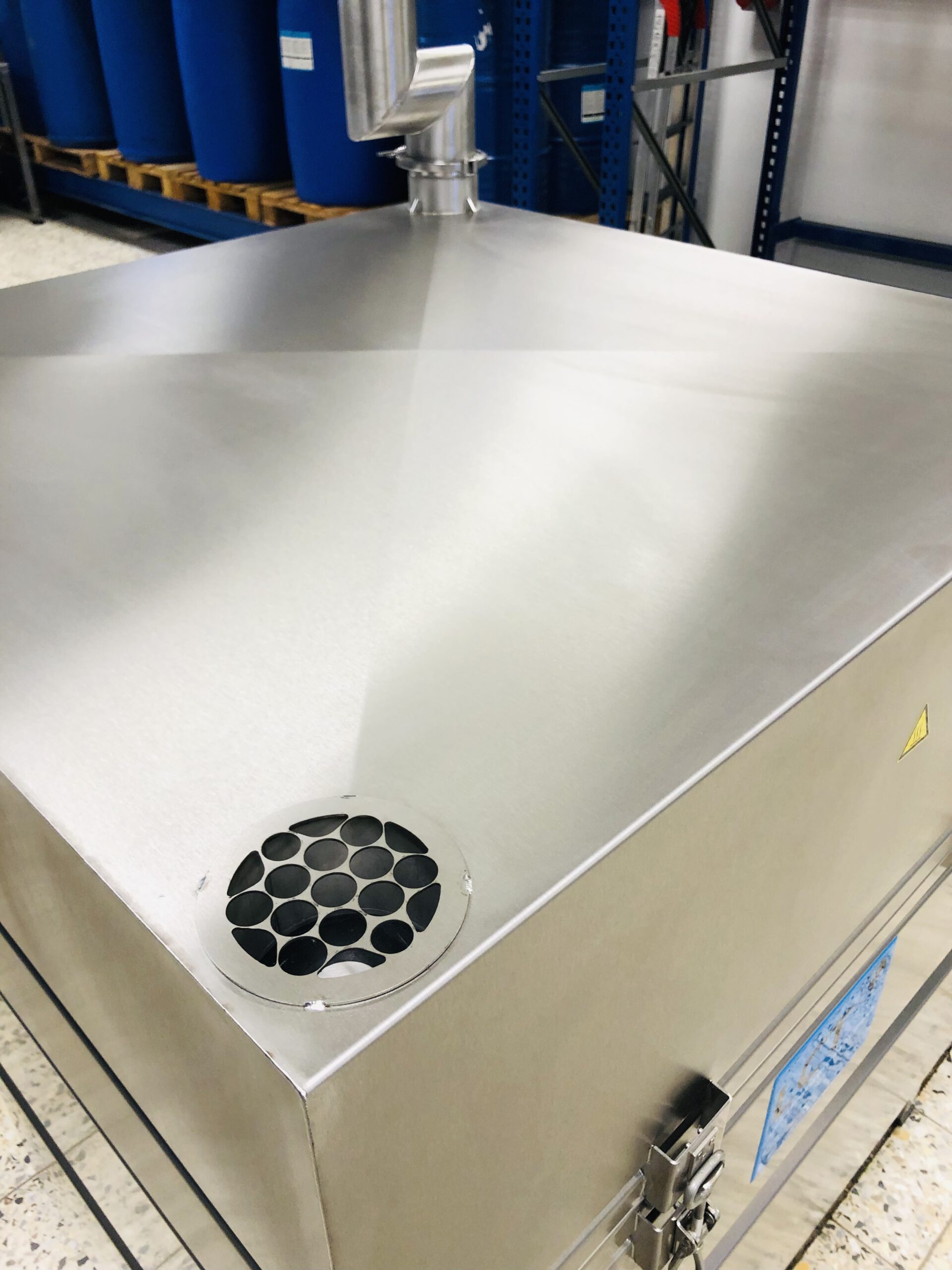

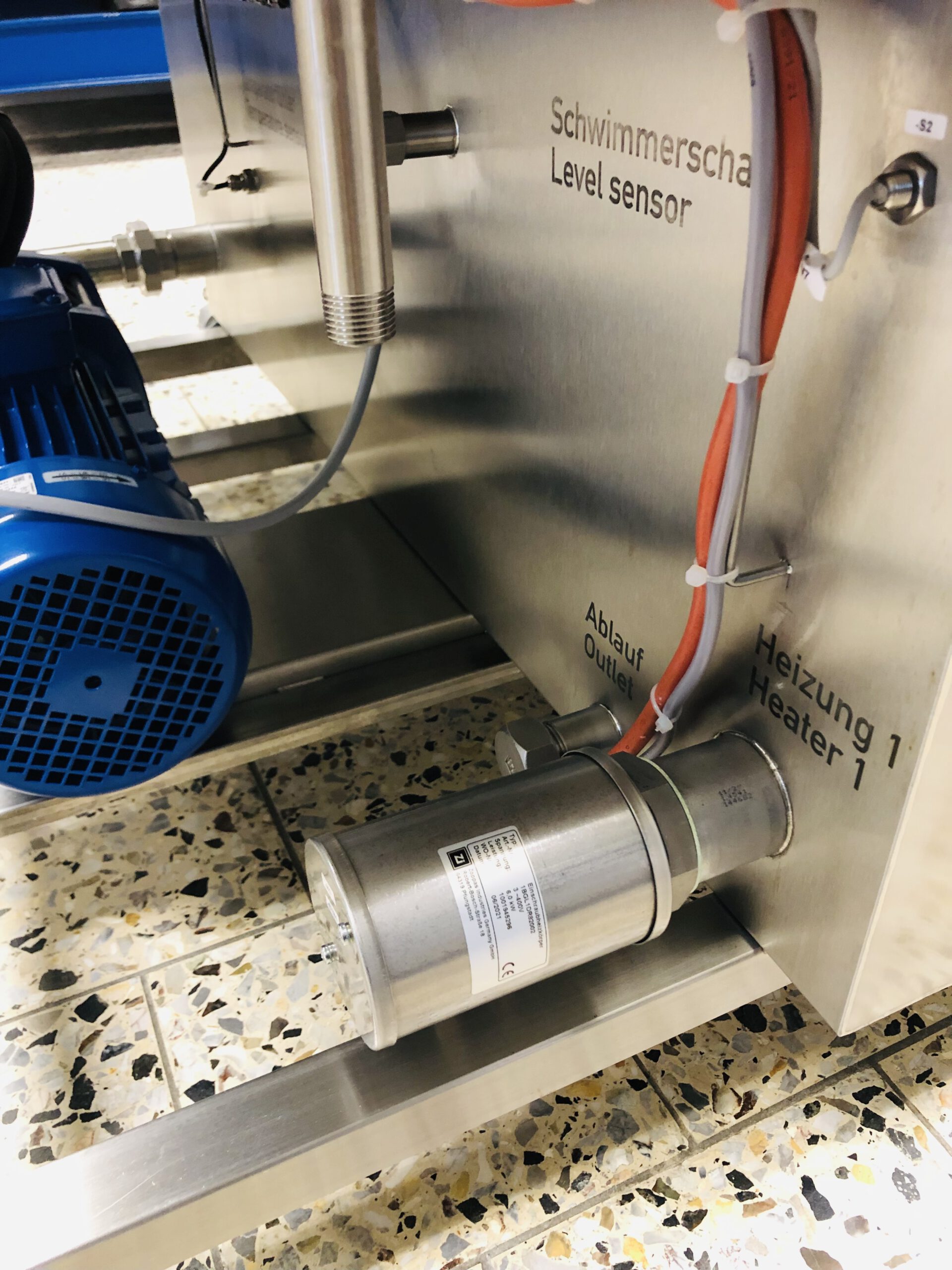

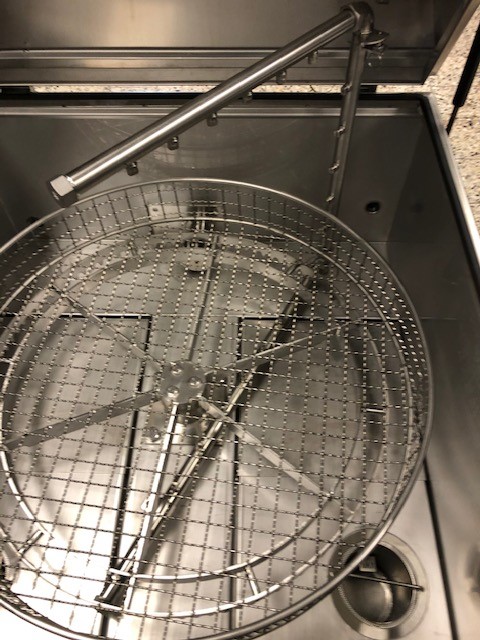

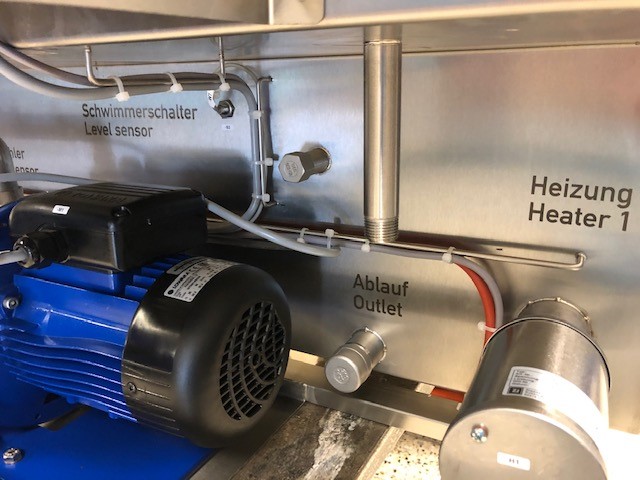

Parts washing system HTW 1500

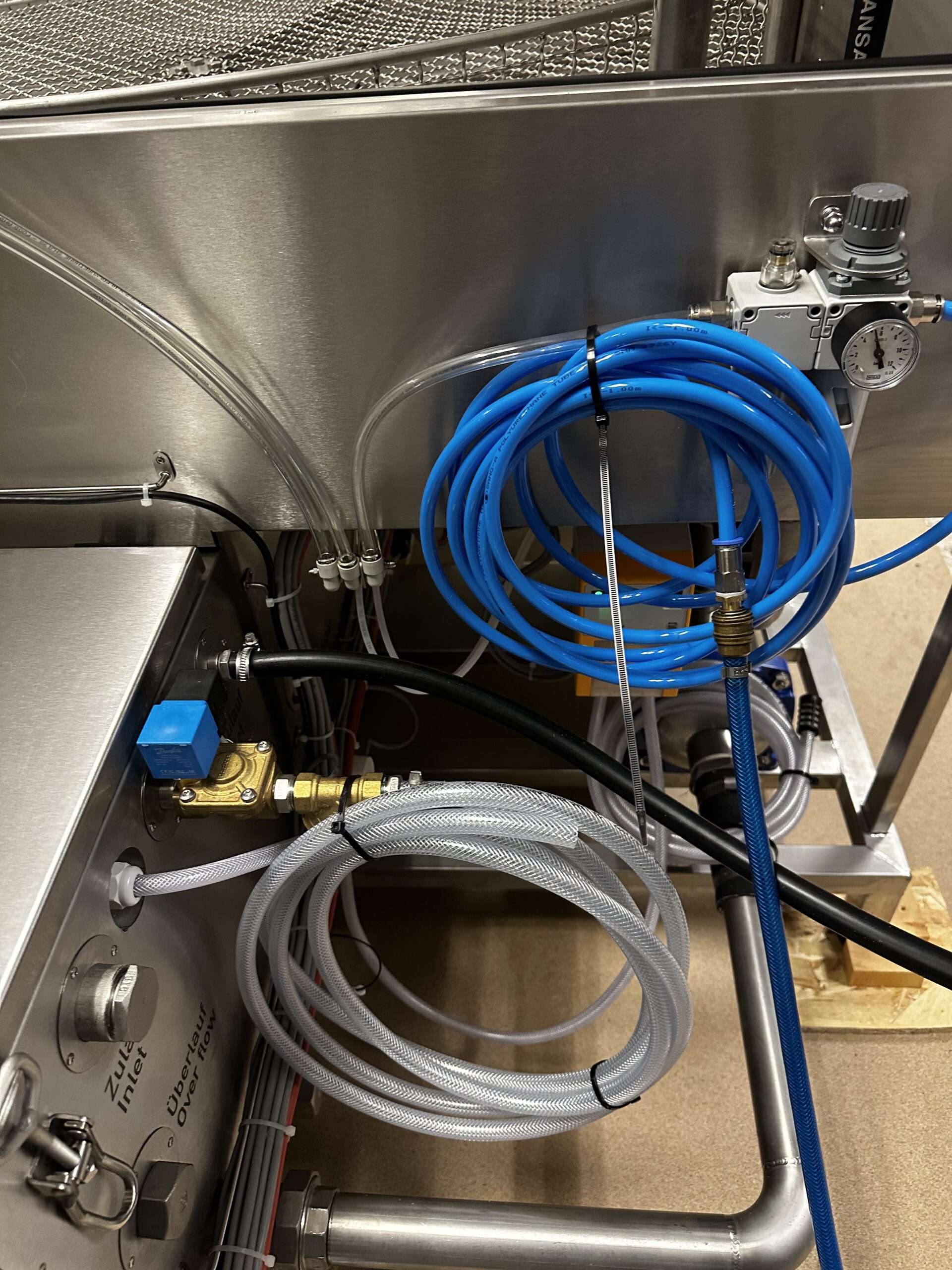

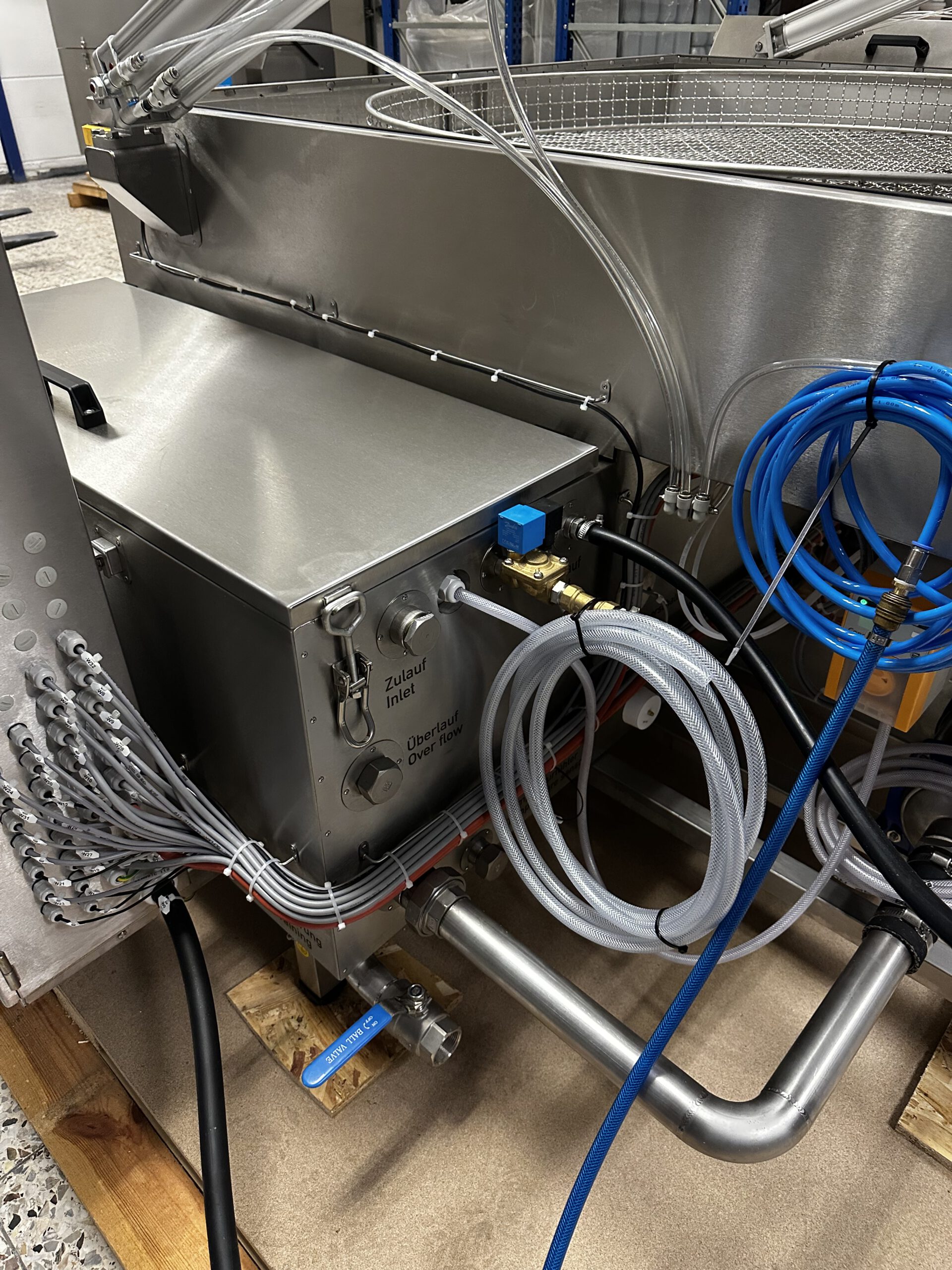

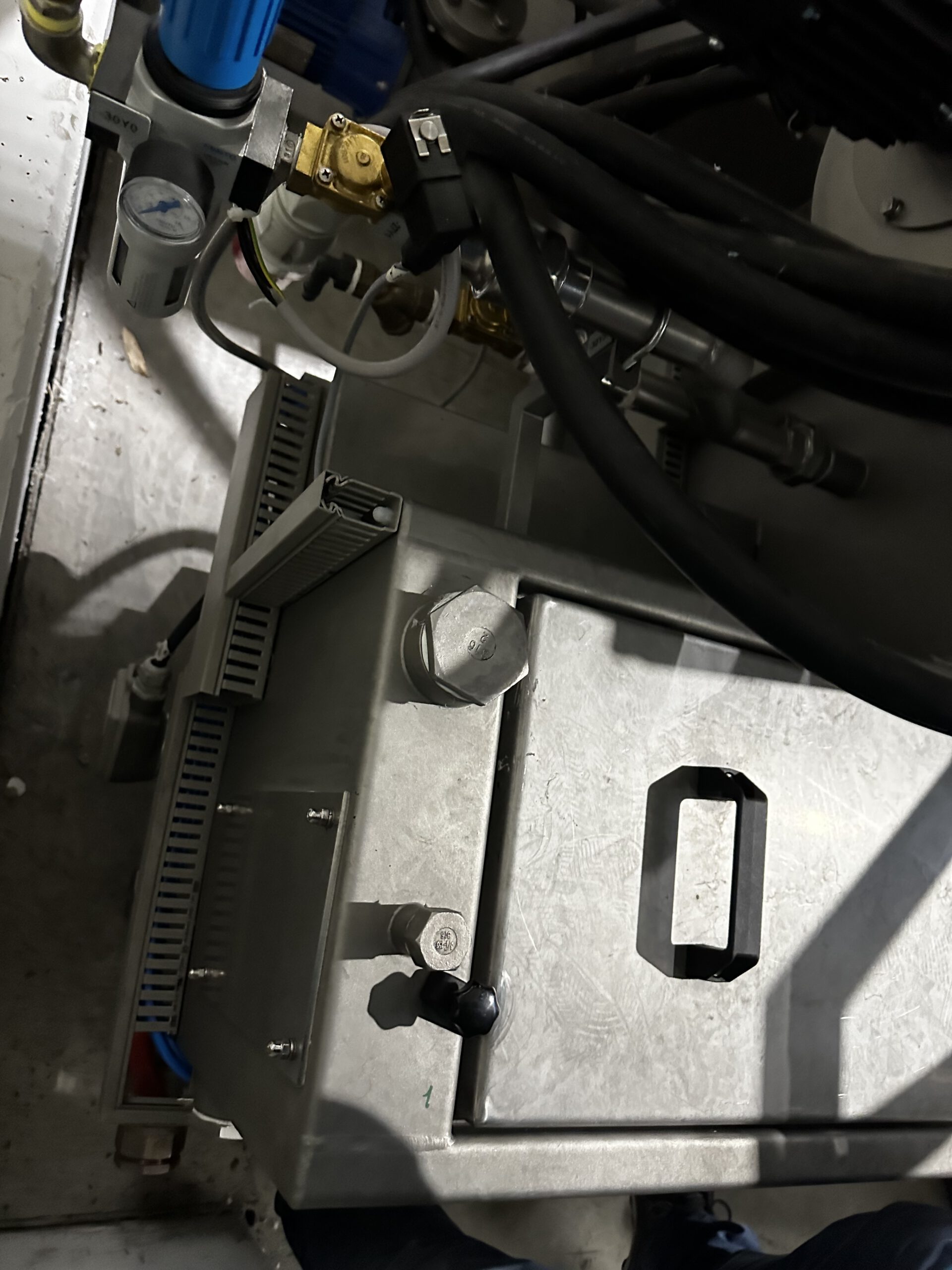

We are selling a HTW 1500 two-chamber washer as a demonstration machine from 2025.

Machine has only been run for demonstration purposes and has the following equipment:

460 liter wash tank with 4 bar pump

Rinsing tank 440 liters with 2 bar pump

Compressed air blow-off

Hot air drying

Insulation wash and rinse tank

Solenoid valves for water filling (wash and rinse tank)

Electrical conductivity measurement for dosing the detergent, detergent is always kept at the set percentage ratio

Optional (canister empty signal via PLC)

Side tank lid for easy maintenance, with locking of the lid

Connections for oil separator and filter system available

Siemens SPS control system

Traffic light system

Machine, pumps and control cabinet made entirely of stainless steel

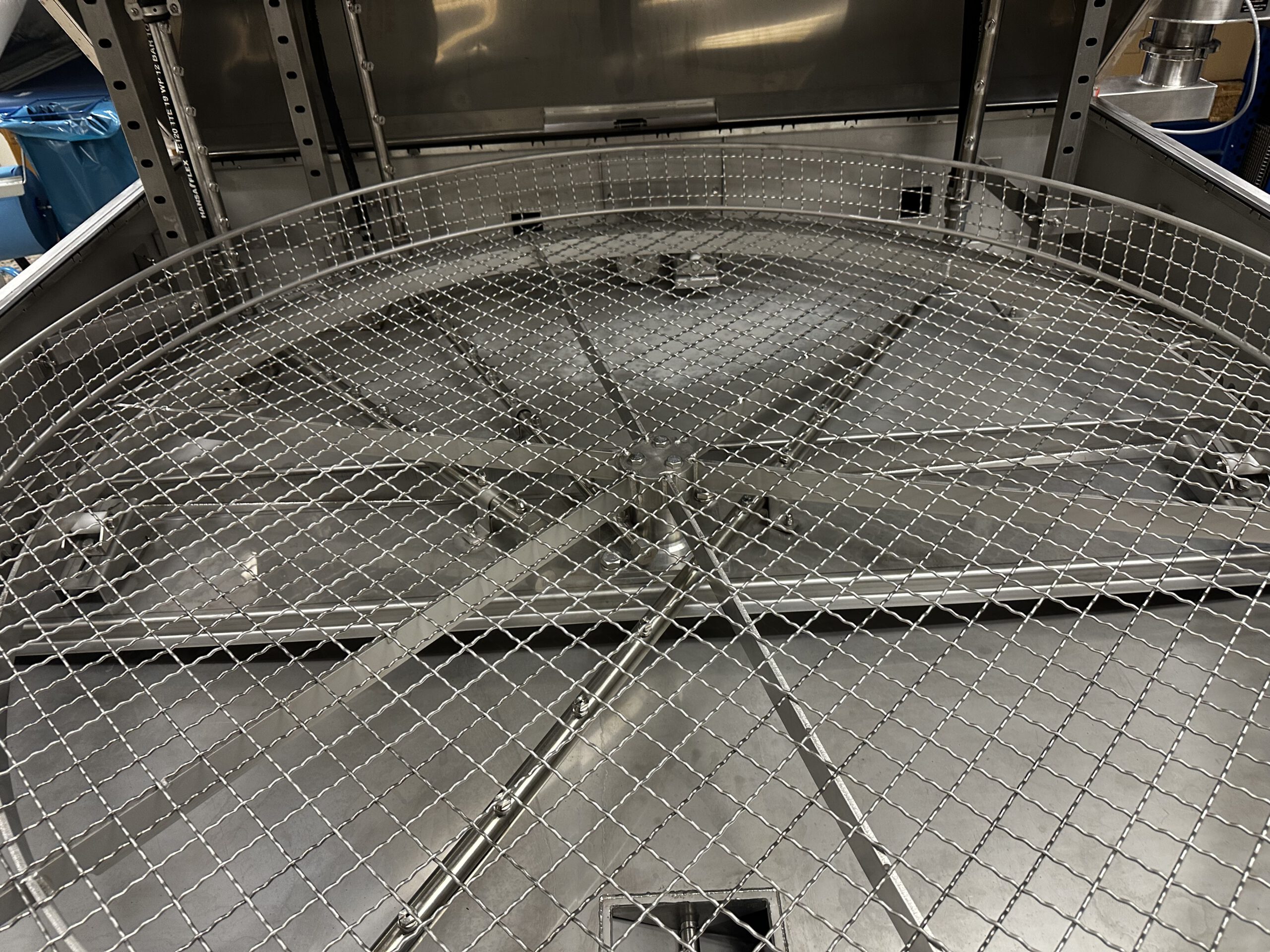

Basket diameter 1500 mm

Basket payload: 350 KG

Usable height under the nozzles: 750 mm

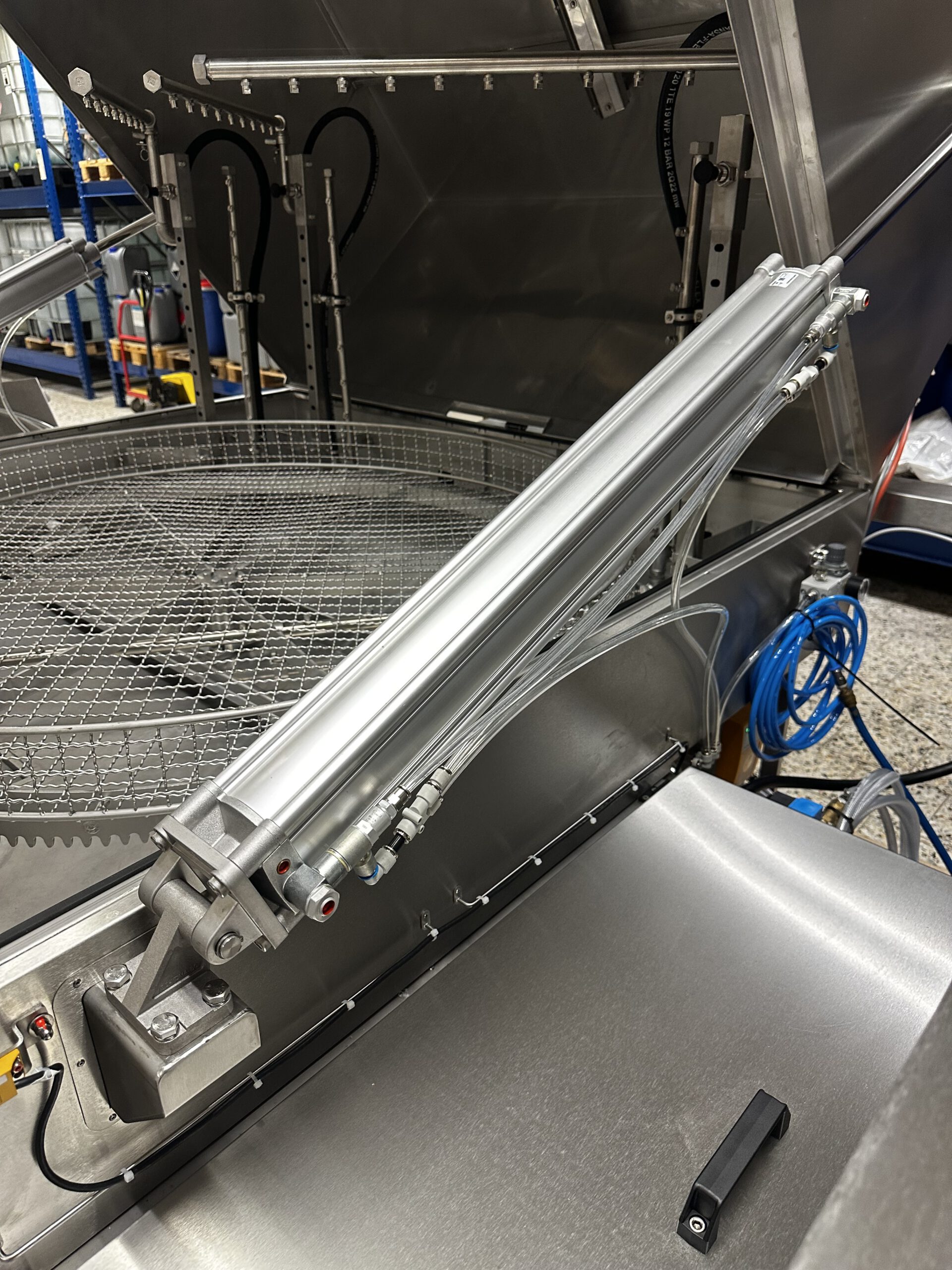

Nozzle pipes are all mechanically height-adjustable

Inching switch for basket rotation (two-handed operation)

Mechanical basket drive via gearbox (no water jet)

Vapor extraction for water vapors

Pneumatic lid opening 80° via two-hand operation

82.990,00 € The price includes 19% VAT

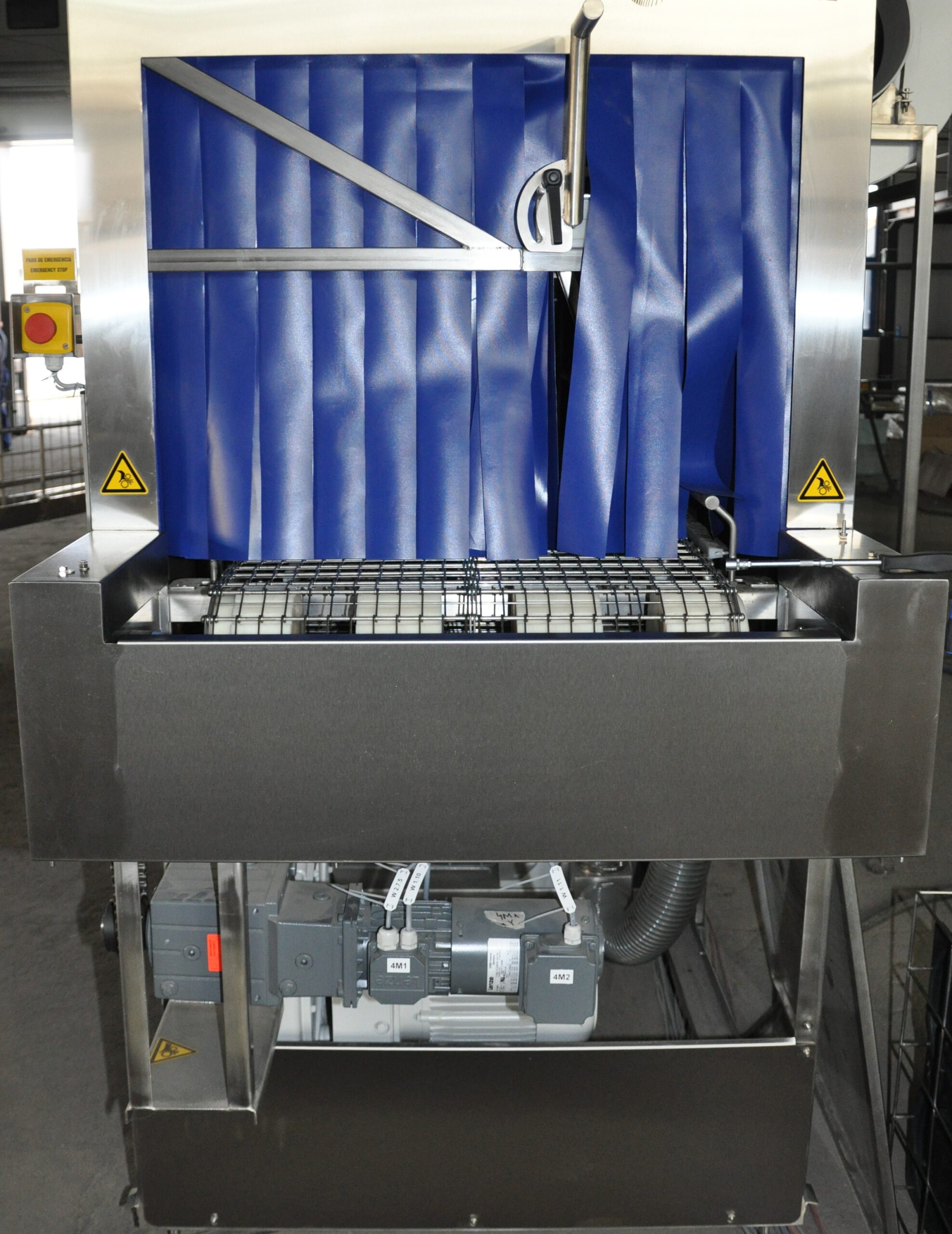

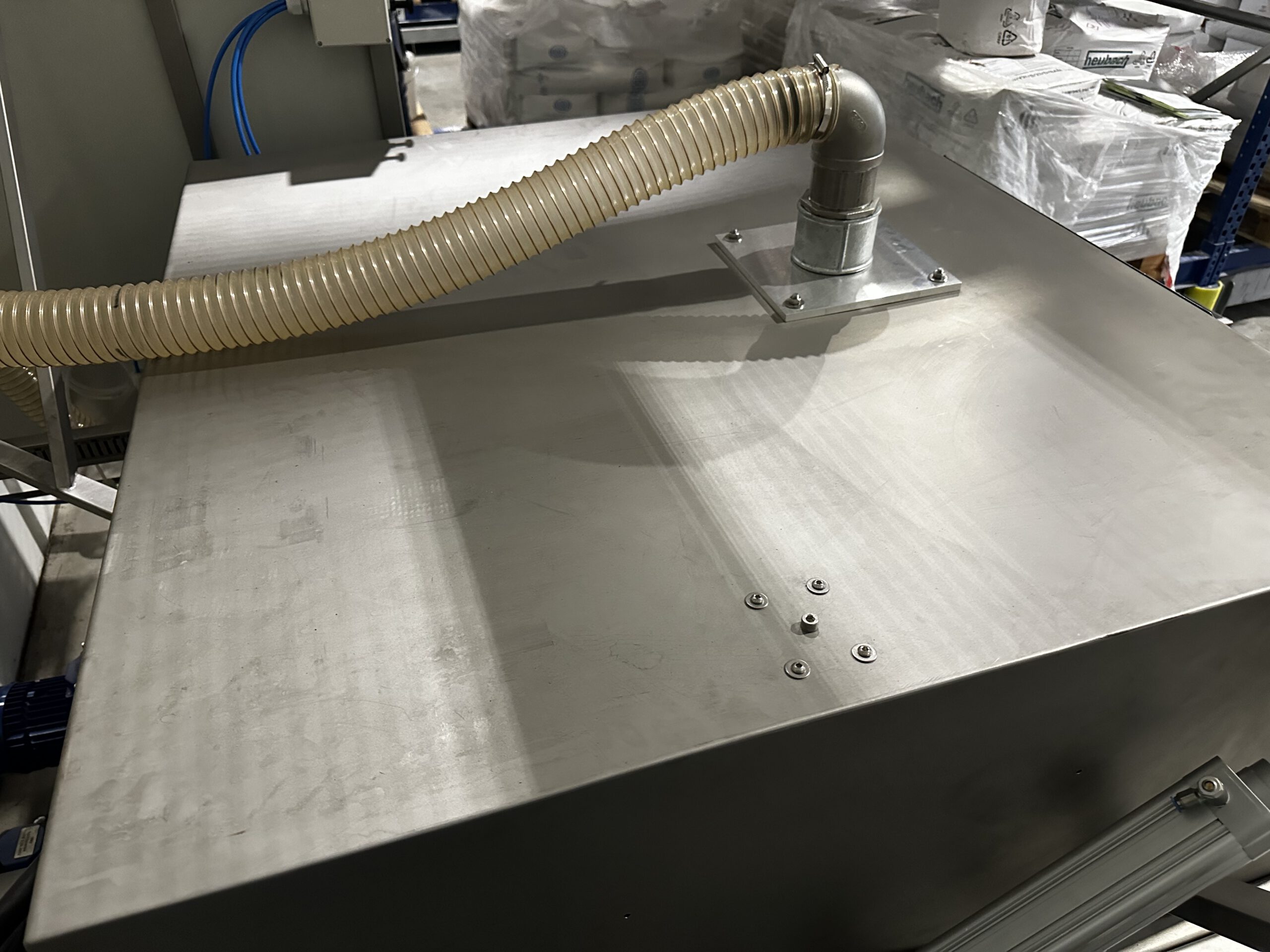

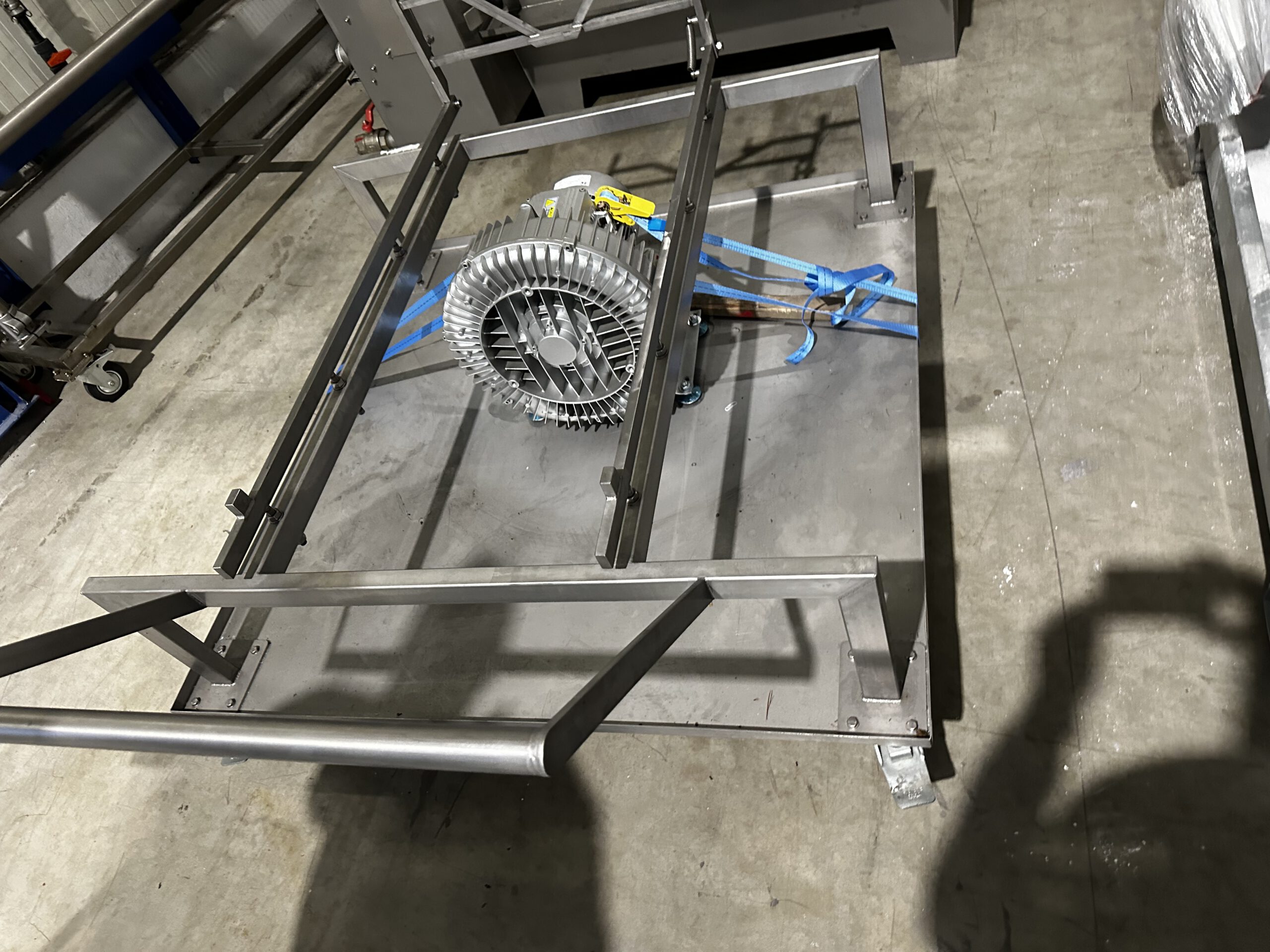

Continuous washing system

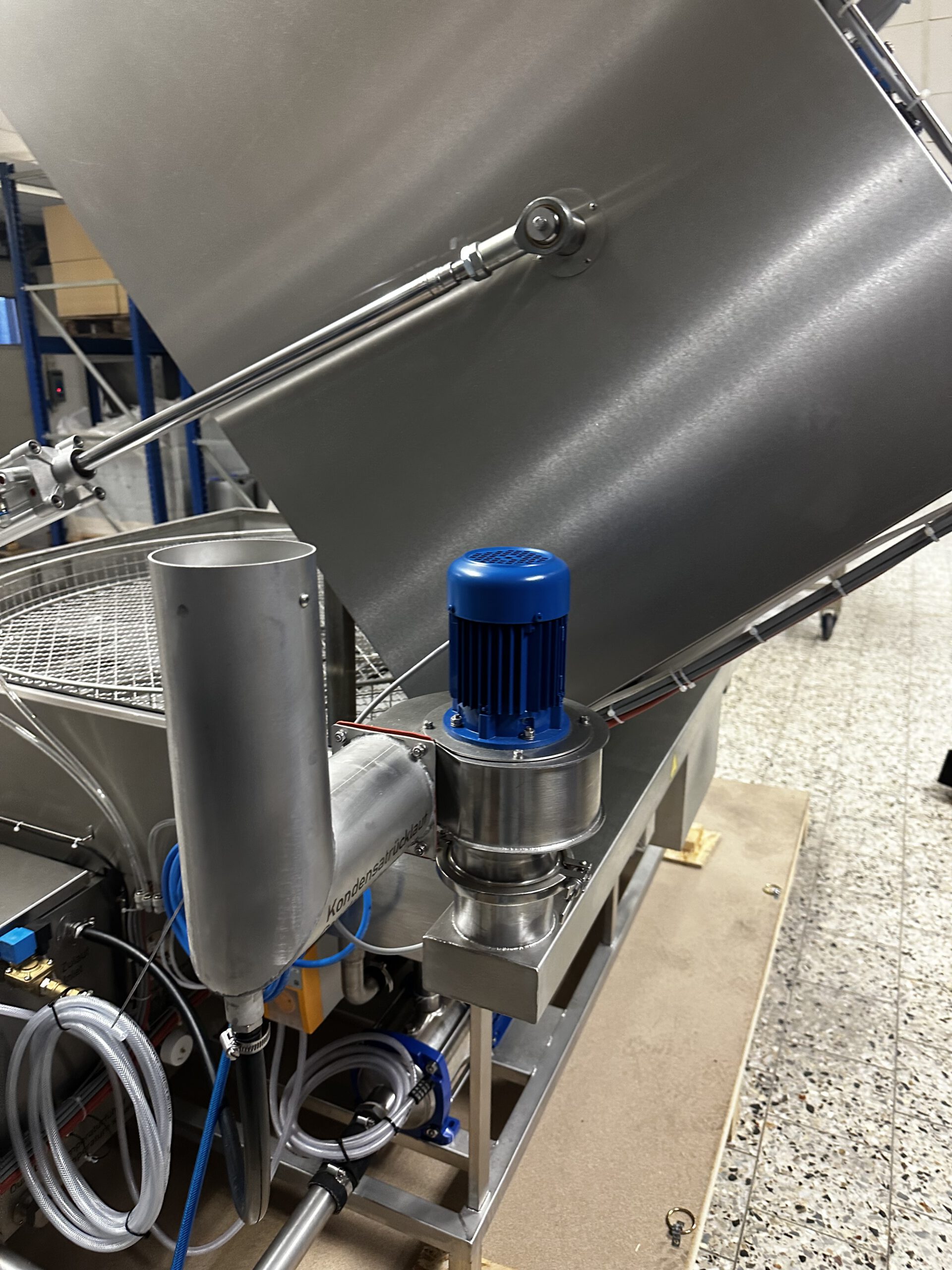

Sale LCT T 600 demonstration tunnel washer from 2024 at a special price incl. 19% VAT.

Zones of the tunnel washer:

Zone 1: Main wash zone:

Length: approx. 2600 mm

Pump: 7.5 kW, 60 cbm/h

Tank capacity: approx. 400 l

Water heated with 3 electric

screw-in heaters 10 kW each

Operating wash temperature: approx. 60° C

The wash items are washed with a water cleaning mixture using a stainless steel centrifugal pump and nozzles in a circuit

The washing zone has an automatic fresh water supply via a solenoid valve, which opens at level min. The detergent is automatically fed into the machine via a dosing pump (conductivity principle) The wash zone has a steam vapor extraction fan, which removes it to the outside via an exhaust pipe.

Vapor condenser available on request (recirculation)

Zone 2: Rinsing zone

Length: approx. 2200 mm

Pump: 3 kW, 33 cbm/h at 3 bar

Tank capacity: approx. 350 l

Water heated with 2 electric

screw-in heaters 10 kW each

Operating wash temperature: approx. 60° C

The wash items are rinsed by means of a stainless steel centrifugal pump

and nozzles in a circuit.

The rinsing zone has an automatic fresh water

supply via a solenoid valve, which opens at level min.

An additional detergent is automatically fed into the machine via a

dosing pump (conductivity principle) so that, for example, a drying aid can be added to the rinsing bath.

Zone 3: Hot air drying zone:

This is used for all-round mechanical air blowing (from below, sideways and above) of the water droplets on the surface of the

the water droplets on the surface of the items to be washed.

air knife and built-in high-pressure fans.

Design and function of the system

The washing machine housing is made entirely of

stainless steel, material no.: 1.4301.

All external housing surfaces are brushed.

The components are washed in the main washing zone using the centrifugal pump and a system of adjustable nozzles

with the addition of an appropriate LCT cleaning agent.

Detergent is automatically added to the main tank via a dosing pump. The wash water temperature is monitored by means of the digital thermocouple built into the tank.

thermocouple built into the tank. The desired process wash water temperature can be thermostatically controlled up to 70 degrees C.

After the main wash zone, the components enter the rinsing zone.

rinsing zone. Here they are rinsed using the centrifugal pump and a system of adjustable nozzles with the addition of water (from the tank) and a drying aid if required.

The drying agent is added automatically via a dosing pump.

The tanks located below the main and rinse wash zone

rinsing zone are equipped with a sieve drawer

(mesh size = 1.5 mm) for the collection of coarse

coarse dirt (labels, chips, etc.) and a fresh water filler neck.

fresh water filler neck.

Drainage takes place via mechanical draining of the nozzles located in the basins, which are pulled out upwards.

The conveyor belt is fitted with a plastic belt.

The frame is made of stainless steel 1.4301, it has its own drive and is controlled via the system’s PLC.

The conveyor belt takes the wash items out of the machine, makes a

a 90° turn to the left and then conveys the goods towards the machine entrance (where the parts to be washed are placed in the washing machine).

the washing machine)

There are 3 photocells mounted at different points on the conveyor belt, with special holders and mutual reflectors on the stainless steel rods. Belt width 400 mm / height up to 400 mm

(At the beginning – 1 sensor before the curve, 1 sensor at the end and 1 sensor approx. 2 m before the end) is a buffer zone (1-2 m long)

As soon as the buffer zone is full with the returning wash ware, the machine stops

the machine and the conveyor belt stop automatically.

The conveyor belt of the washing system is made of stainless steel and is variably controlled by a frequency converter.

Throughput 20 to 40,000 items per week (5 days / 8 hours) possible

Complete power consumption 92 KW, during operation approx. 50 KW

249.000,00 € The price includes 19% VAT

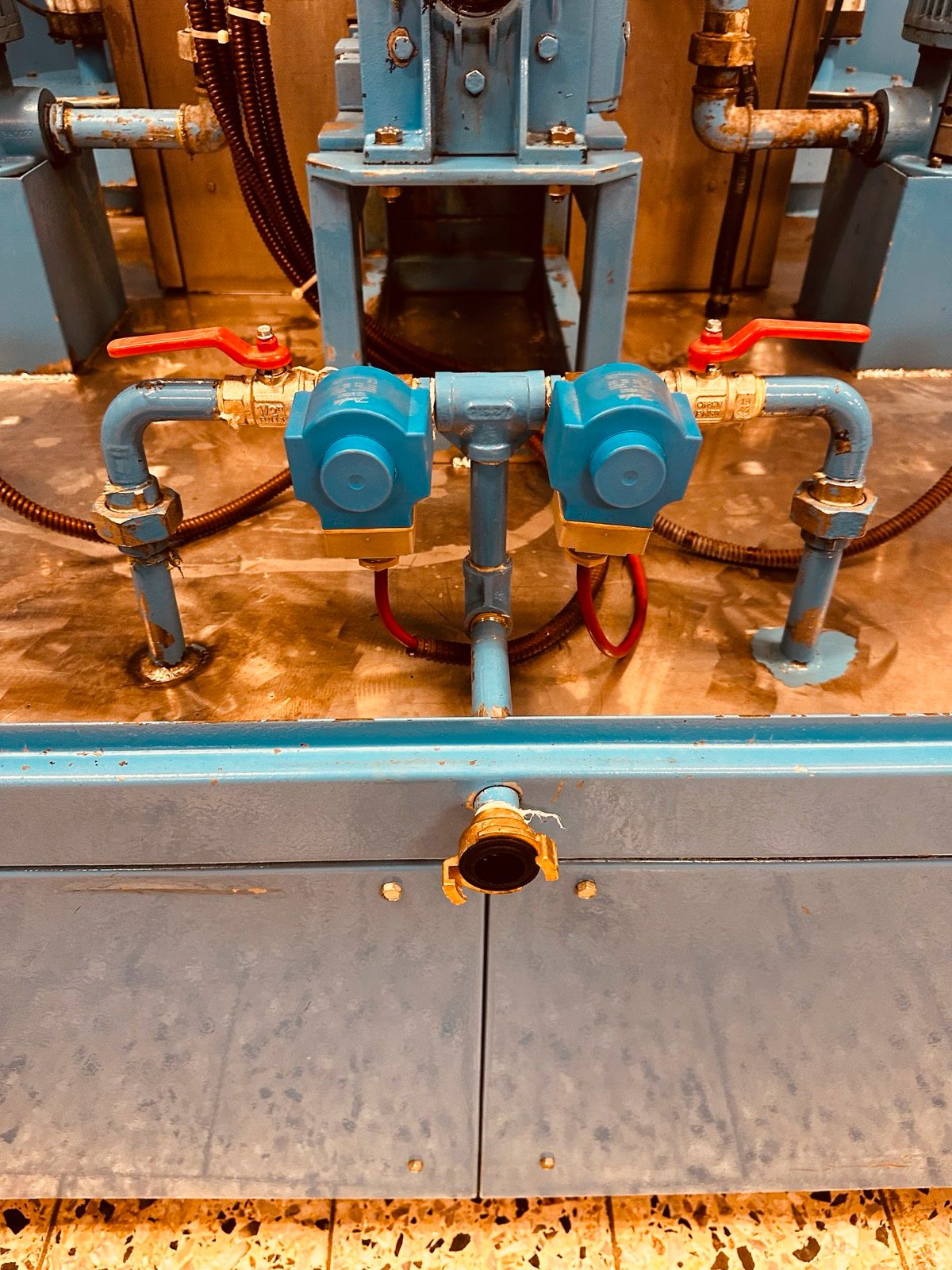

Laborex two-chamber parts cleaning system

The price includes 19% VAT

We are selling a Laborex two-chamber parts washer as good as new, ideal for maintenance operations, but can also be used for all other washing tasks.

Type: Loborex R-12-RVS-W/E-2T

Two-chamber system with washing and rinsing function with blower drying (cold air), a heating cartridge could be retrofitted

Transport trolley for easy loading and unloading

Pneumatic lid opening via push-button

Pneumatic switchover from washing to rinsing

Siemens KTP 400 control system, see picture

2 x2 filter pots for dirt collection integrated in the return flow (wash tank and rinse tank)

Machine installation dimensions: 2300 x 2420 x 2500 mm (width x depth x height)

Basket diameter 1180 mm

Usable height inside: 500 mm

Load capacity wash basket: 350 KG

Wash tank capacity: 560 liters

Rinsing tank capacity: 130 liters

Voltage: 400 Volt

Maximum power consumption: 23 KW 38 A

Compressed air maximum 10 bar, minimum 6 bar to control lid and slider (change from washing to rinsing)

Water connection 1/2” maximum pressure 6 bar

Outlet 2 x 2” (wash tank / rinse tank)

Wash pump pressure 5 bar

Rinsing pump pressure 2 bar

Year of construction 2023, only been in operation as a demonstrator, therefore completely as good as new

2 large maintenance flaps for wash and rinse tank

Steam vapor extraction

Detergent dosing can be retrofitted on request

System can be delivered and commissioned on request

Complete operating instructions, circuit diagram and spare parts list available

Price: € 59.990,00 € The price includes 19% VAT

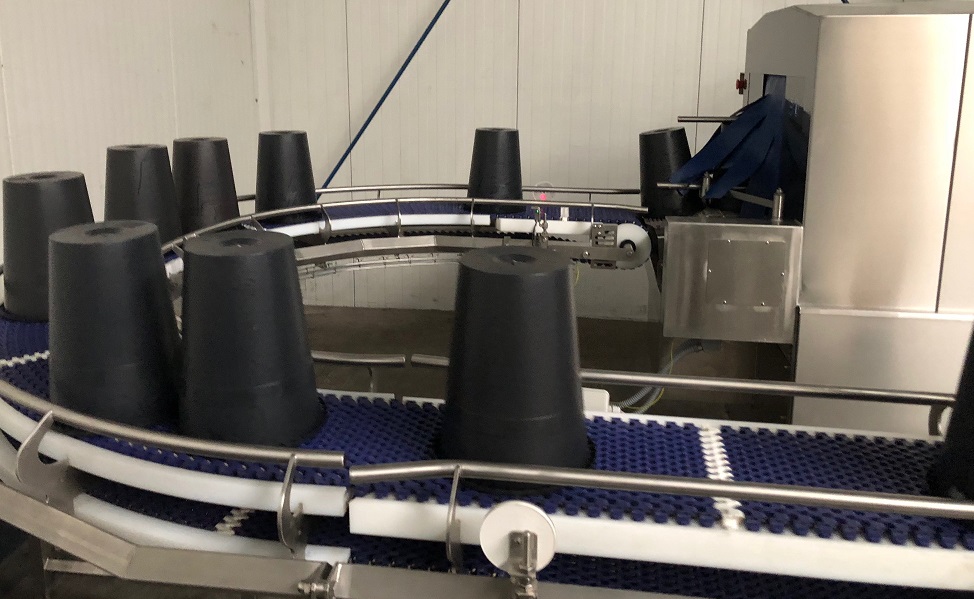

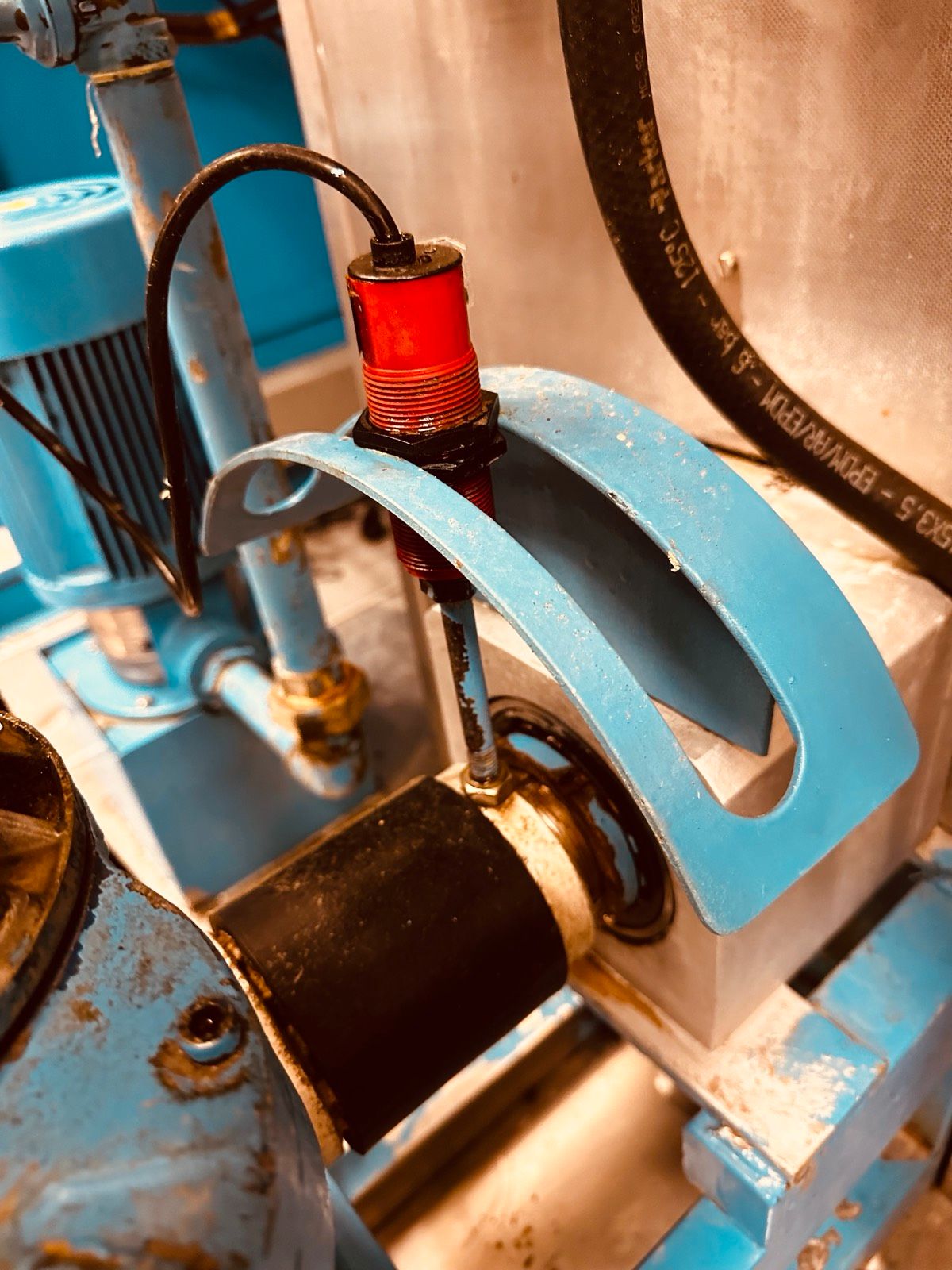

Franke drum washing system

We are selling a used Franke drum washing system for washing bulk goods, mainly for turned and milled parts.

System features:

Tanks made entirely of stainless steel

600 liter washing tank with 18 KW heating

600 liter rinsing tank with 18 KW heating

Insulation of both tanks

Weekly timer for the heating

Washing drum can be switched using a rotary switch, rotates 360° or remains stationary when washing and rinsing, including speed sensor Exhaust fan with 900 m3/hr.

Oil separator via large disc skimmer with tub and ball valve automatic water dosing / Geka coupling at the rear 2 washing baskets 530 x 300 x 200 mm with clamping lid, mesh size 6×6 mm

50 KG load capacity per washing basket

Pneumatic door opening and switching from washing to rinsing

Front frame as basket support to be attached with 4 M12 screws Drain taps for washing and rinsing tank and two large maintenance hatches

Good accessibility on all sides, 2 x folding doors at the front and the remaining side walls can be removed using quick-release fasteners Rexroth pneumatics

Grundfos stator pump in the washing and rinsing tank

63 A Mennekes plug with 5 meter cable

Rital control cabinet with accessories inside

Operating instructions

Machine ready for use immediately

Installation dimensions width 3 meters, depth 2.3 meters with basket table, height 2 meters

Delivery and commissioning possible after consultation and cost assumption

Invoice with 19% VAT is shown

If you have any further questions, please write or call

5500,00 € The price includes 19% VAT

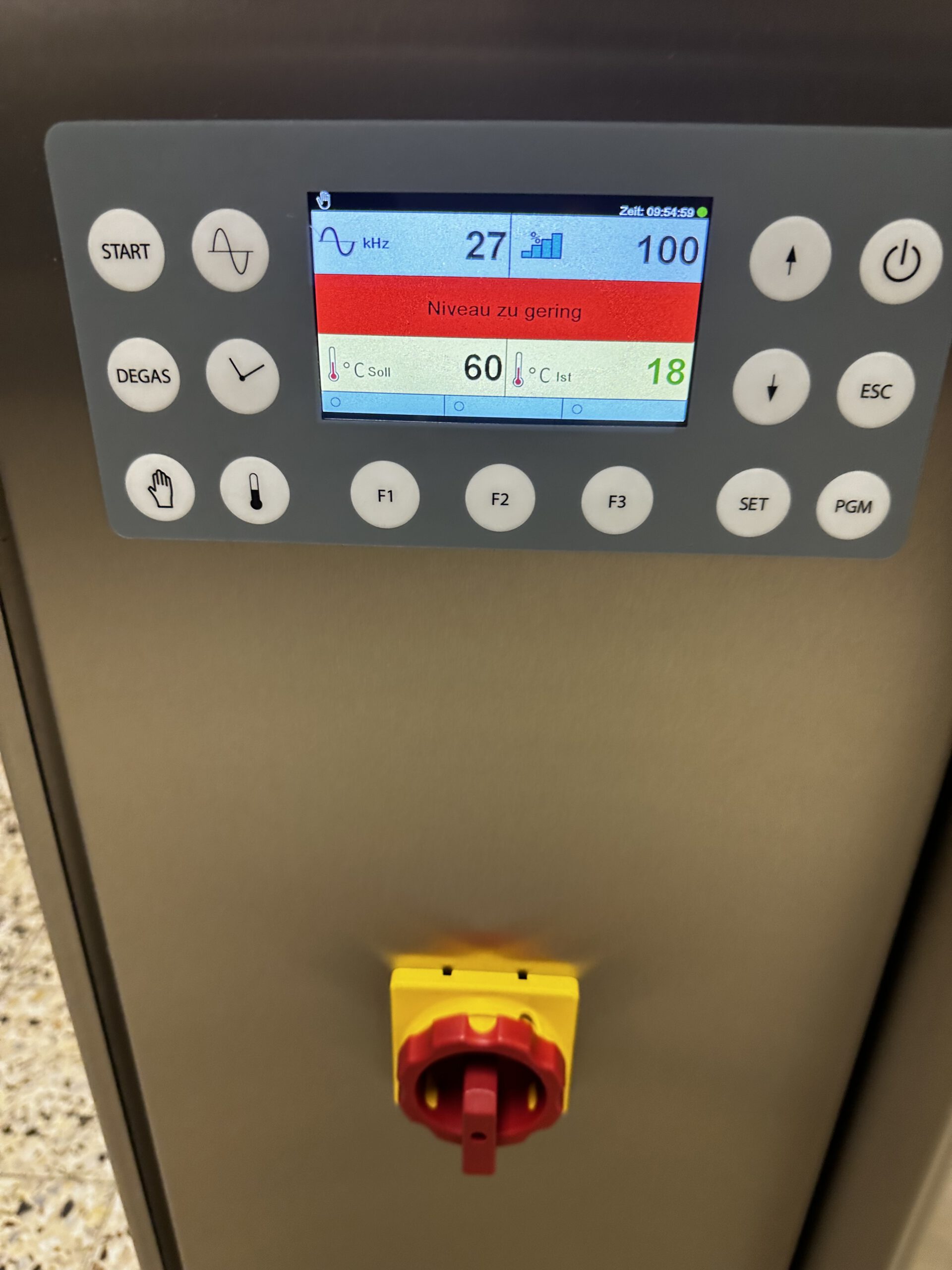

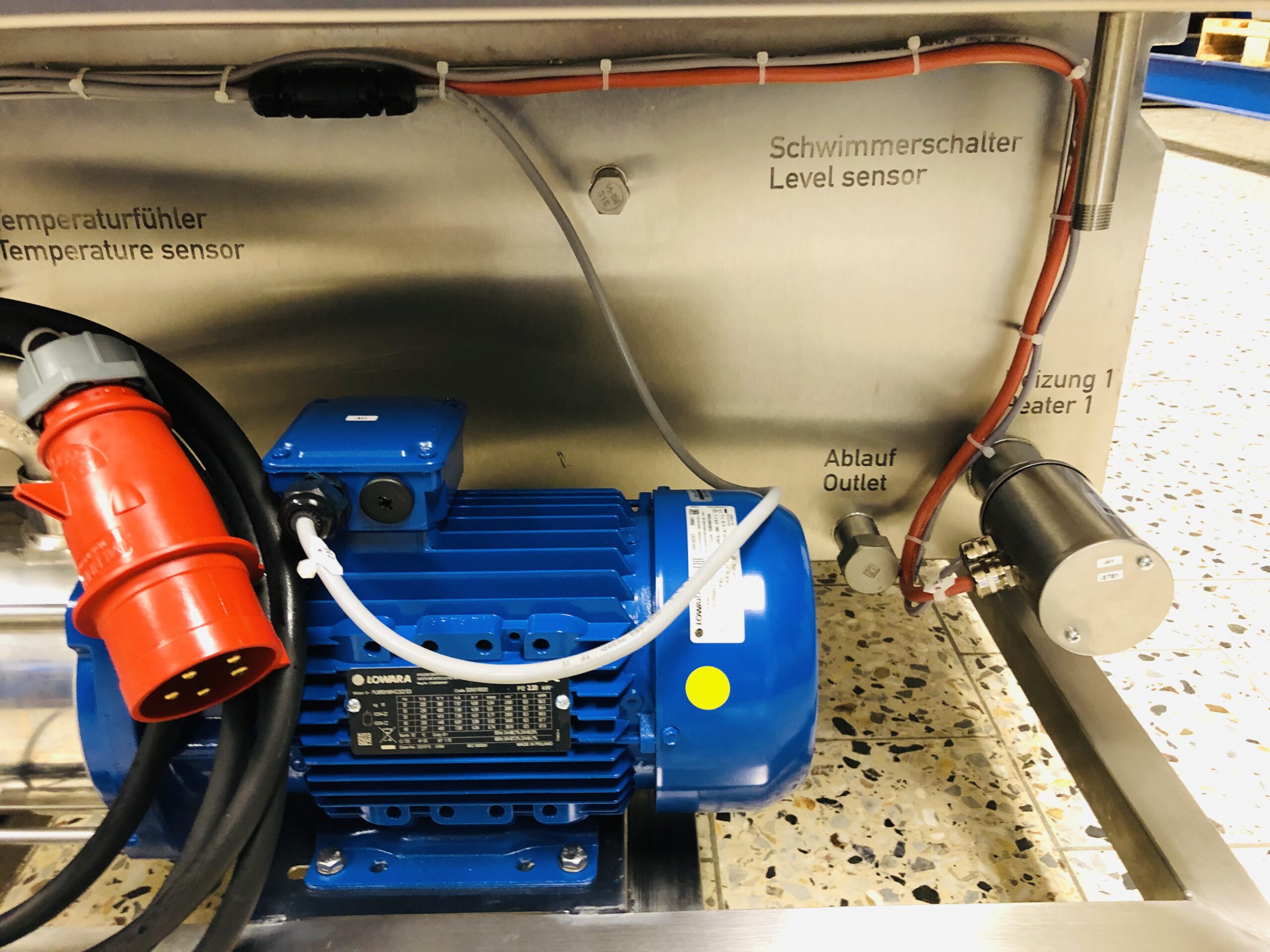

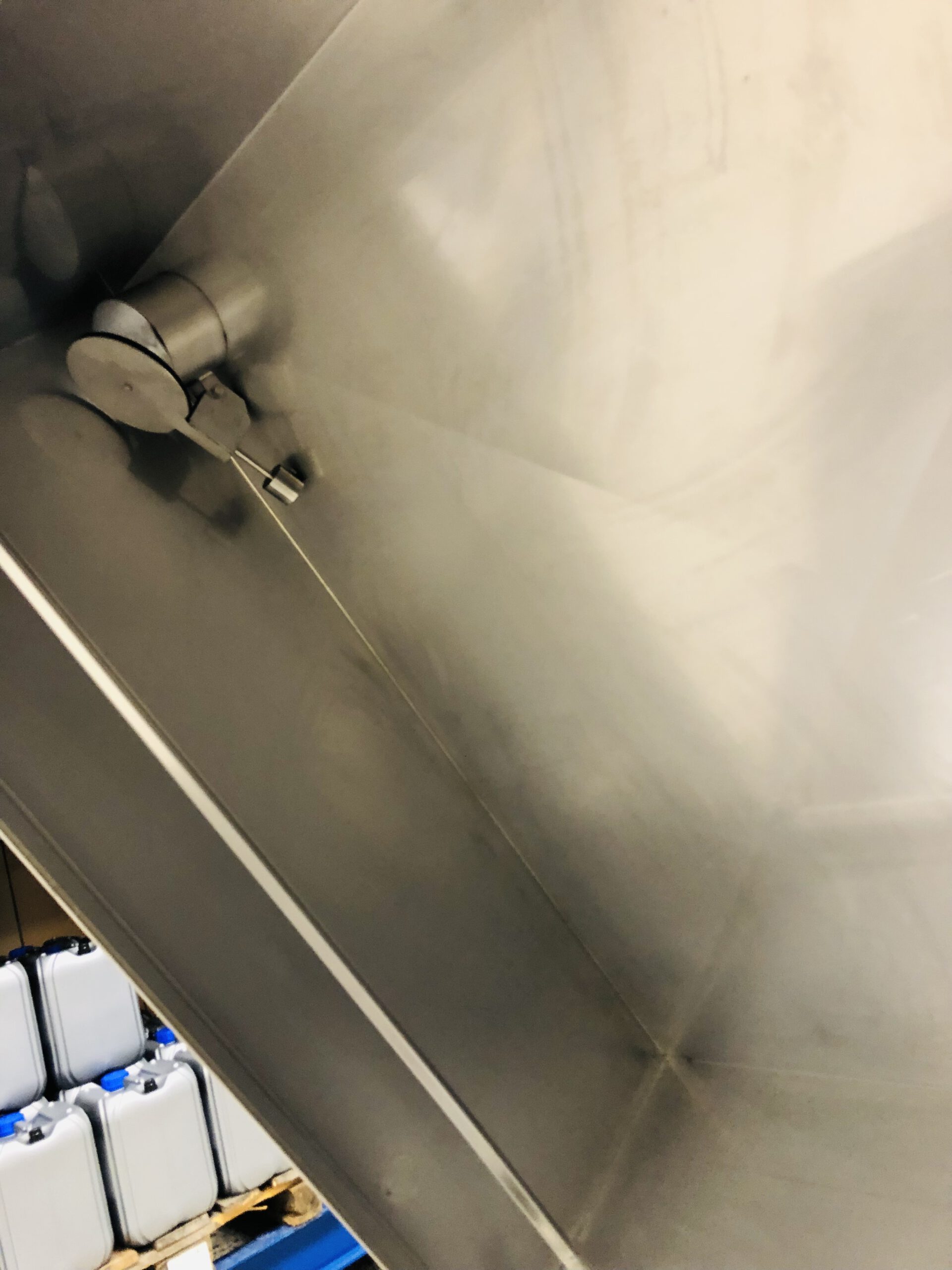

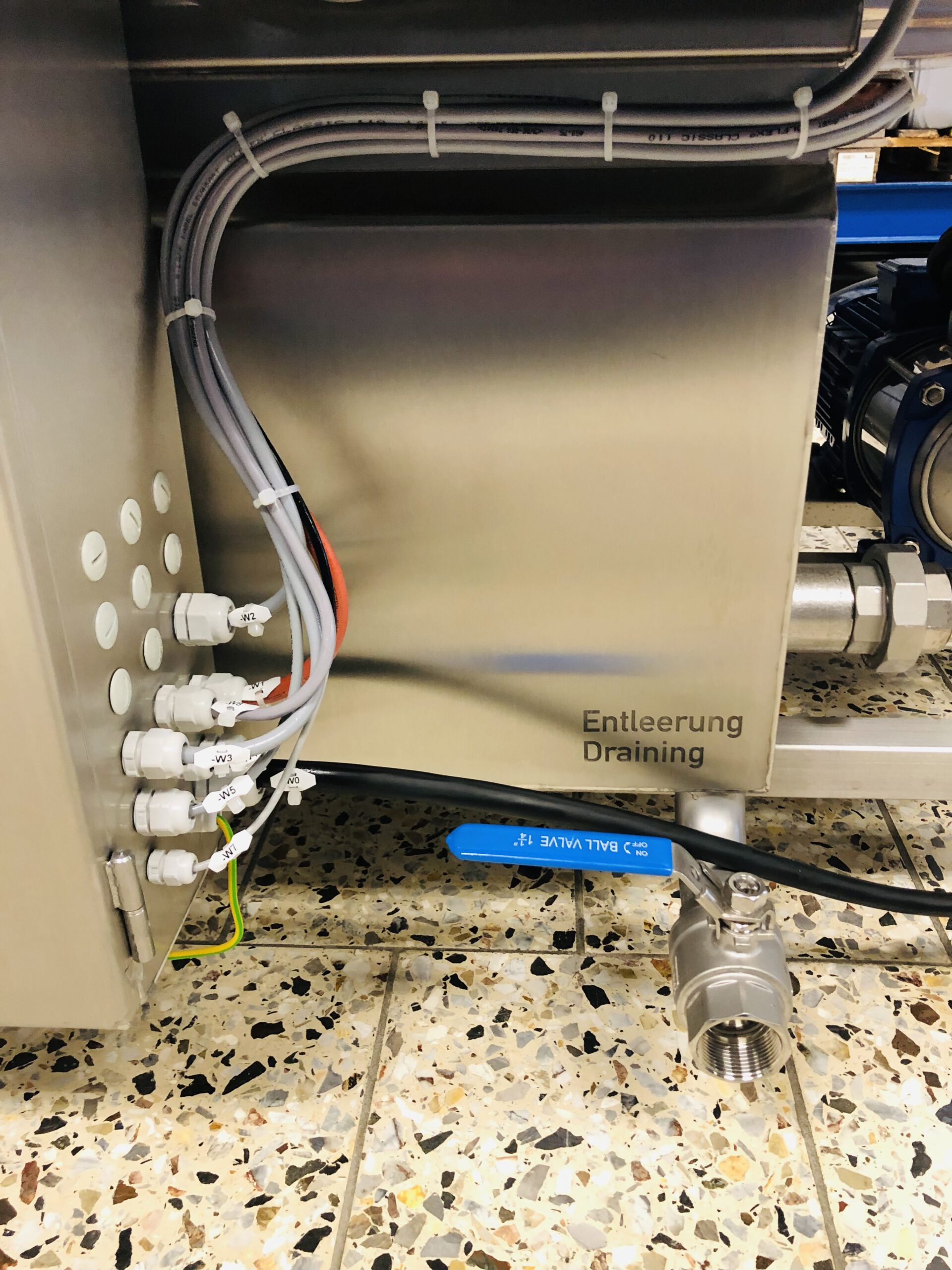

LCT ultrasonic cleaning tank type NW 180

LCT NW 180 BSS ultrasonic demonstration tank

Dual frequency 27/80 kHz

Infinitely variable ultrasonic control from 100-10% power

Tank interior dimensions: 800 x 500 x 600 mm (L x W x H)

Washing basket interior dimensions: 700 x 400 x 450 mm (L x W x H)

Ventilated stainless steel control cabinet

Hinged lid

Tank completely insulated

Stainless steel washing basket with four crane eyes and a basket rod for lifting

Four adjustable feet for uneven floors

Floor emptying via ball valve with slanted tank floor for complete emptying

Floor grate / parts cleaning also possible without basket (engine and gear parts etc..)

Floor and 2 x side sound with a total output of 3000 watts

Timer with timer and program control

Connected load 10.2 KW

Delivery and commissioning by arrangement and Cost coverage possible

If you have any further questions, please write or call

Price: €36,500.00 The price includes 19% VAT

Parts washing system HTW 1000

Standard: Without insulation as standard

Machine made entirely of stainless steel including washing pump

– Automatic basket drive

– Touch button for rotating the basket outside of the cleaning procedure

– Tank cover and sieve filter under the basket made of stainless steel

– Dry run protection

– Door safety switch

– Connections for plate phase separators (oil separators)

– Inner basket width 975 mm

– Usable height of basket to lower edge of nozzle block 450 mm

– Flat jet nozzles

– Washing pressure 3 bar

– including 20 KG LCT Power Star 50-730

24 month guarantee

Price: €15,719.00 The price includes 19% VAT

Parts washing system HTW 800

Parts washing system HTW 1200

Standard: Without insulation as standard

entirely of stainless steel including washing pump

– Automatic basket drive

– Touch button for turning the basket outside of the cleaning procedure

– Tank cover and sieve filter under the basket made of stainless steel

– Dry run protection

– Door safety switch

– Connections for plate phase separators (oil separators)

– Inner basket width 1180 mm

– Usable height of basket to lower edge of nozzle block 675 mm

– Flat jet nozzles

– Washing pressure 4 bar

– Return bend as a condenser for low water consumption

– including 20 KG LCT Power Star 50-730

– 24 month guarantee

Price: €18.528.00 The price includes 19% VAT

Parts washing system HTW 1500

Standard: Without insulation as standard

Fully automatic small parts washing system for single-stage cleaning and degreasing

– Machine and washing pump made entirely of stainless steel

– Automatic lid opening 80° via pneumatic control

– Operating pressure 4 bar

– Digital temperature control

– Automatic basket drive

– Touch button for turning the basket outside of the cleaning procedure

– Tank cover and sieve filter under the basket made of stainless steel

– Dry run protection

– Door safety switch

– Connections for plate phase separators

– Fan nozzles

– Basket diameter 1500 mm

– Basket payload 350 KG

– Usable height between basket and nozzle holder 750 mm

– Tank capacity 600 liters

Incl. 20 KG LCT Power Star 50-730 for all applications

– 24 month guarantee

Price: €30.356.00 The price includes 19% VAT

100% tracking

We can provide the processes in our modern washing and ultrasonic systems with corresponding barcodes, so that 100% traceability of the just washed and processed parts can always be given.

All messages and statuses of the systems can be communicated to you in real time on your smartphone if desired, so the production management is always up to date on the current status of the system and the throughputs currently being run.

To the LCT online shop

Our product range contains a large number of high-quality products for a wide variety of requirements.

Request information

Feel free to request further information on specific topics by e-mail!

Our service

We would be happy to visit you in person at your site and coordinate the cleaning process that suits your manufactured product, so that you too can make an effective contribution to environmental protection in the future.

Contact us at any time!

Please fill in the adjacent fields or call us.

E-mail address

info@laue-cleaning-technology.de

Phone | Fax

+49 (0) 5 71 / 38 60 14 99

+49 (0) 5 71 / 38 61 05 05

Address

Lindenstraße 31

DE-32457 Porta Westfalica

Request further information

Please send me further information by e-mail on the following topics: