Filter systems

Filter systems

LCT filter systems integrated into the machine process or as a stand-alone solution, the right application for every process.

· in the preparation of cooling lubricants

· in sewage technology

· in the filtration of foodstuffs

· in the sludge post-drying…

Special constructions possible at any time after preliminary tests

LCT filter systems

Models

Dump-bed filter systems

Rising bed filter systems

Mud presses

Cleaning centrifuges

Bag filter systems

To the LCT online shop

Our product range contains a large number of high-quality products for a wide variety of requirements.

Request information

Feel free to request further information on specific topics by e-mail!

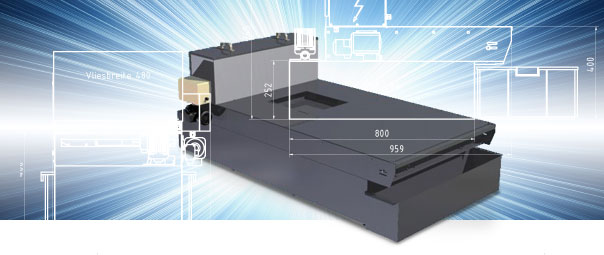

Dump-bed filter systems

The LCT trough bed filter systems work according to the principle of gravity filtration:

A patented, specially shaped transport chain pulls a filter fleece over a trough. The liquid to be filtered is directed into the trough, onto the filter fleece. The fine particles retained with the help of the filter fleece clog the filter fleece.

Result:

The liquid no longer drains through the filter fleece, the level of the liquid in the trough rises.

A level sensor mounted above the filter lake starts the feed motor via electric control, the transport chain pulls the soiled fleece out of the filter lake and transports it into the waste container. At the same time, new, clean fleece is unrolled, the level of the filter lake sinks again, the whole process repeats.

Variants:

- with filter fleece in stainless steel and plastic

- without filter fleece only in plastic

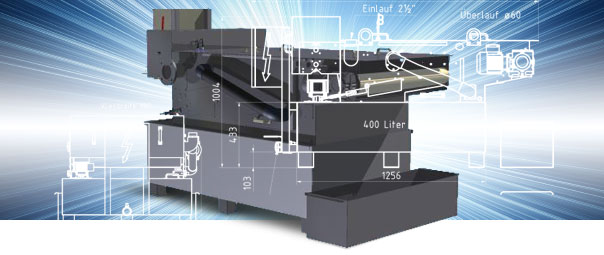

Rising bed filter systems

Powerful, compact filter for high demands.

The concept:

The liquid to be filtered is directed onto the filter fleece web. The dirt particles are retained on the filter fleece. The cleaned liquid flows into the reservoir and can be drained back from there for reuse or disposal.

The residue left on the fleece forms a so-called filter cake. If the density of the filter cake prevents optimal drainage of the liquid, the filter cake is automatically transported together with the fleece into a waste basin. The whole process is continuous and fully automatic, without interrupting the flow of liquid.

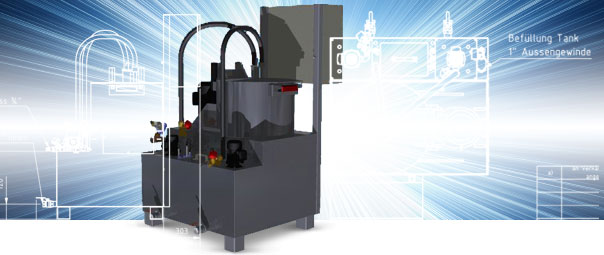

Mud presses

Mechanical sludge dewatering is used to reduce the amount of sludge by separating sludge water. The result is a more or less solid mud cake.

The LCT belt press removes residual moisture from almost all slurries by up to 95%. And it does so fully automatically, continuously, without the interruptions to operation necessary for cleaning in comparable other applications. This process results in a significant reduction in the weight of the wet sludge, which in turn results in a substantial reduction in disposal costs.

Cleaning centrifuges

For separating ultra-fine particles from liquids.

The LCT cleaning centrifuges (PMZ) remove fine sludge from water, waste water, emulsions, grinding and cutting oils safely, gently and in an environmentally friendly manner.

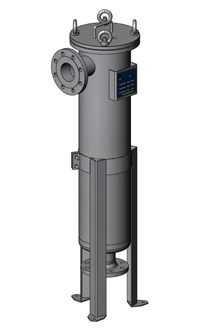

Bag filter systems

Welded stainless steel constructions for holding a size 1 or 2 filter bag. They consist of a vertical, cylindrical container shell with moulded cast lid and receptacle. The lid is sealed by an O-ring and is hinged and remains on the housing when opened. The closure is made with eye bolts and ring nuts. The filter insert is reliably fixed in place by means of an infinitely adjustable hold-down. Both filter bags with plastic collars and those with sewn-in steel rings are sealed bypass-free. Additional connections as well as a cast-on screw-on surface on both sides enable the quick attachment of a differential pressure gauge. The filter housings are electropolished inside and out and are supplied with a height-adjustable base as standard. The filter housings are designed for the filtration of fluids of fluid group 2 (non-hazardous).

Trial requests

We would be happy to visit you on site with our LCT mobile on wheels to give you a practical demonstration of our products..

You are welcome to send us your soiled or residue-laden production parts and we will find the right cleaner or cleaning process for your application.

In our technical centre, we can simulate all application processes, from simple dipping to spraying to ultrasound or high-pressure processes.

Contact us at any time!

Please fill in the adjacent fields or call us.

E-mail address

info@laue-cleaning-technology.de

Phone | Fax

+49 (0) 5 71 / 38 60 14 99

+49 (0) 5 71 / 38 61 05 05

Address

Lindenstraße 31

DE-32457 Porta Westfalica

Request further information

Please send me further information by e-mail on the following topics: