Ultrasound cleaning

Ultimate cleanliness with ultrasonic cleaning –

Effective removal of stubborn dirt

Ultrasonic cleaning is an innovative and efficient method of thoroughly cleaning a wide range of materials and objects. With the ability to remove even the most stubborn dirt, ultrasonic cleaning offers a first-class solution for numerous cleaning requirements.

Ultrasonic cleaning uses the power of ultrasonic waves and a suitable cleaning fluid to efficiently remove soiling. This technology creates tiny bubbles in the cleaning fluid that implode and create a strong pressure. This process, known as cavitation, removes dirt and debris from the surface of the item being cleaned.

Ultrasonic cleaning is particularly effective when cleaning complex or finely structured objects. It is used in many industries, from medical technology and the automotive industry to jewelry manufacturing. It offers safe, environmentally friendly and thorough cleaning that is superior to conventional cleaning methods.

There are a variety of ultrasonic cleaning devices on the market, varying in size, performance and price. Whether you need a large industrial device or a small device for home use, there is an ultrasonic cleaning solution to suit your needs.

The benefits of ultrasonic cleaning are undeniable. With its ability to deep clean while maintaining the surface integrity of the items being cleaned, it offers an invaluable solution to a wide range of cleaning requirements. In today’s world where cleanliness and hygiene are of paramount importance, ultrasonic cleaning is a technology that cannot be ignored.

So, if you’re looking for an effective, efficient and environmentally friendly cleaning solution, consider ultrasonic cleaning. It could be just what you need to take your cleaning processes to the next level.

LCT models

Devices for ultrasonic cleaning

LCT

Expert Line

LCT ultrasonic cleaning units NW

LCT

Poly Line

LCT

Compact units

LCT

KTR-KTRO

LCT

Lift-Shift systems

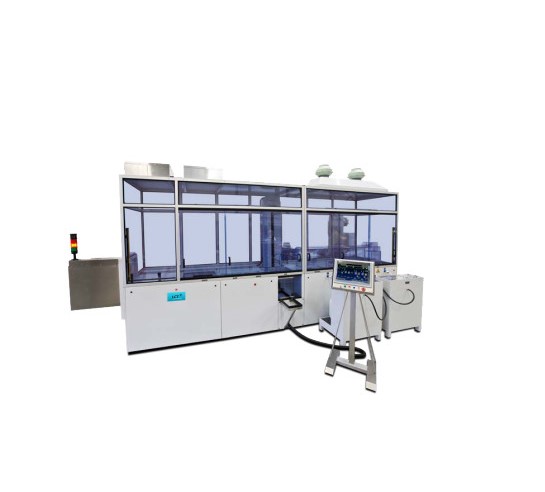

LCT Automatic linear systems

LCT Generators and transducer systems

LCT

Lift-Line

LCT

Cell-Cleaning Unit

To the LCT online shop

Unsere Produktpalette enthält eine Vielzahl von qualitativ hochwertigen Produkten für die unterschiedlichsten Anforderungsgebiete.

Request information

Fordern Sie gerne weitere Informationen zu bestimmten Themen per E-Mail an!

LCT Expert Line

The ultrasonic and rinsing tanks in the USW and SPW series are robust and reliable devices for industrial cleaning. They are characterized by their wide range of applications as well as their high and constant power output.

Special features:

- State-of-the-art ultrasonic technology

- SINGLE and DUAL frequency technology

- Highest cleaning efficiency

- Customized dimensions

- Lateral sound

- Oil skimmer and overflow pocket

- Pump filter system

- Fabric movement

- Electropolished tank

- VE water treatment

- Made-to-measure baskets

LCT Ultrasonic cleaning units Type NW

The LCT-NW series ultrasonic tanks are robust and reliable devices for the industrial cleaning of large workpieces. They are characterized by their wide range of applications as well as their high and constant power output.

Special features:

- State-of-the-art ultrasonic technology

SINGLE, DUAL and MIX frequency technology - Highest cleaning efficiency

- Customized dimensions

- Overflow pocket / equalizing tank

- Pump-filter circuit

- Oil separator / oil skimmer

- Sliding cover / automatic cover

LCT Poly Line

The powerful compact device for ultrasonic cleaning

The ultrasonic and rinsing tanks in the Poly series are robust and reliable devices for industrial parts cleaning. They are characterized by their wide range of applications and their high, constant power output. The devices are available in a wide range of designs and combinations.

LCT Hub Line

Robust systems for ultrasonic cleaning of large or heavy workpieces

Lifting units attached to the trays automatically lower themselves into the bath and optimize the cleaning effect for complicated or delicate workpieces by moving the fabric vertically.

If all lifting units are in the upper position, the baskets can be moved manually to the next bath.

LCT Compact units

Individual solutions – compact design

Cleanliness in the intermediate or final cleaning of high-quality products or components is a sensitive quality feature.

The cleaning processes must be reproducible and individually tailored to the product in question. The LCT Compact systems combine these characteristics at the highest level thanks to their modular design, the use of DUAL ultrasonic frequency technology and the user-friendly control system.

Special features:

- 4 standard tub sizes

- State-of-the-art SINGLE, DUAL and MIX frequency technology

- PLC control

- Automatic, reproducible process sequences

- Operation via touch panel

- Many integrable options

- Process-specific equipment

LCT Cell cleaning

Compact multi-chamber cleaning systems

- State-of-the-art technology in ultrasonic cleaning

- SINGLE, DUAL and MIX frequency technology

- Highest cleaning efficiency

- The system can be operated without a water or waste water connection and can therefore be integrated directly into the production line

- Made entirely of stainless steel

- Tank insert made of cavitation-resistant stainless steel 1.4462

- Cleaning and rinsing bath with integrated filter circuit

- System is mobile

LCT KTR-KTRO

Individual solutions – compact design

Gentle fine cleaning and maximum reproducibility.

Special features:

- Compact design

- Simple, easy-to-understand operation and maintenance of the system

- State-of-the-art ultrasonic cleaning with DUAL and MIX frequency technology

- Automatic process sequence

- Made entirely of stainless steel

- Gentle fabric movement

LCT Lift-Shift systems

Intensive cleaning with high throughput

The automatic pusher unit moves all baskets one cycle at a time to the next bath. In addition, lifting units optimize the cleaning result by moving the goods vertically during treatment.

The automatic transport system ensures maximum continuity and reproducibility with high system performance.

Automatic linear systems from LCT

For the highest demands

An integrated, automatic transport system guarantees maximum reproducibility of the often very demanding processes.

The high-performance systems are equipped with industrial control systems that record and process all process-relevant data as required, thus enabling integrated or external data management or archiving.

LCT generators and transducer systems

As cleaning requirements in terms of quality and cleanliness are becoming ever more demanding, Laue Cleaning Technology GmbH has combined coarse and fine cleaning in a standardized DUAL generator system.

The FT-MG generator is designed for industrial use with high outputs and bus connections to higher-level control systems. Thanks to its compact design, the LCT- FT-MG generator offers maximum efficiency and flexibility with a small footprint.

The FT-TM generator is designed for industrial use with outputs of up to 2000 watts. Thanks to its compact design, the LCT- FT-TM generator offers maximum efficiency and flexibility with a small footprint.

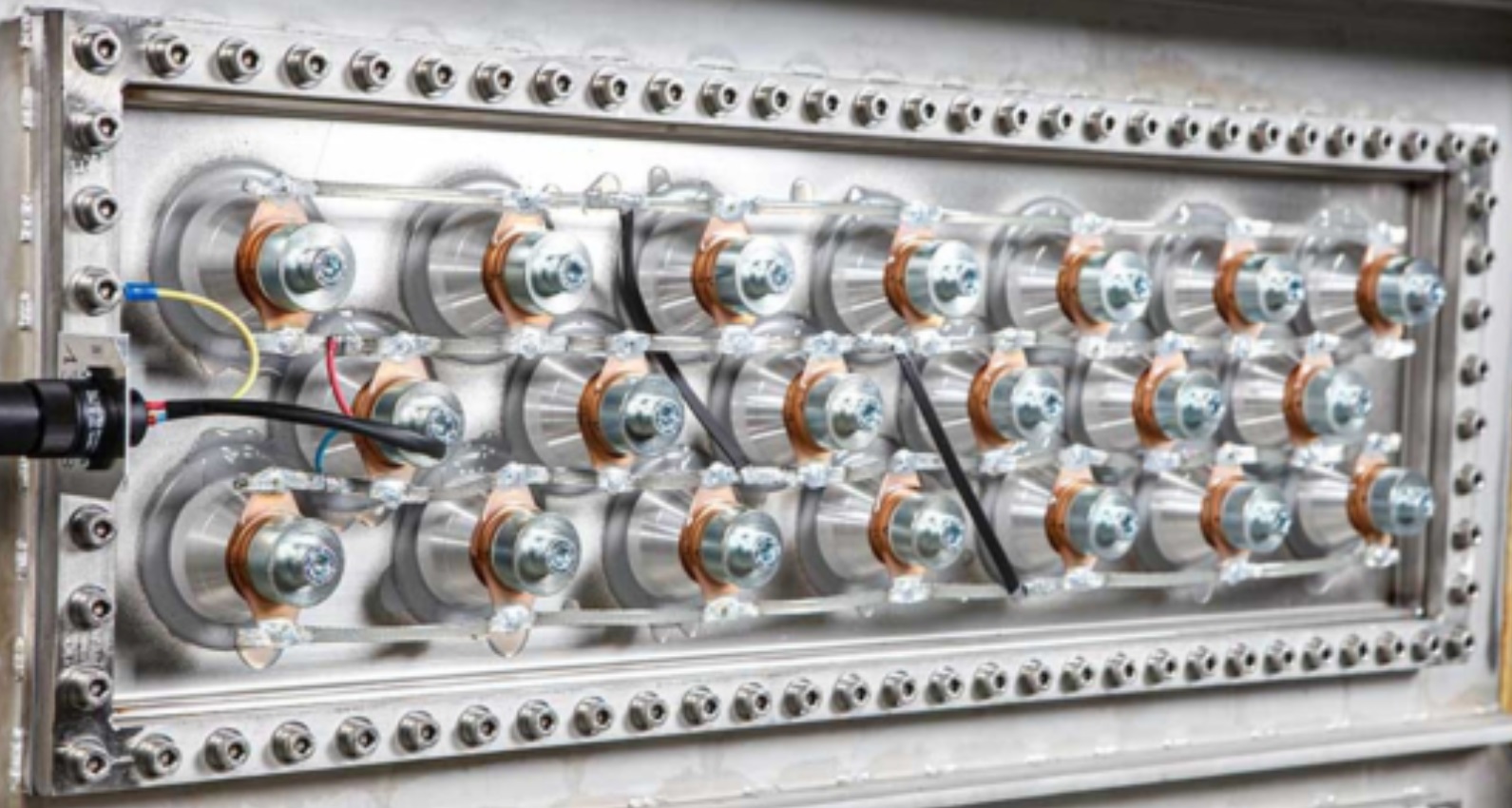

LCT surface transducers can be attached to the bottom or side walls of the tank, depending on the application. There are also LCT immersible transducers for use in very aggressive media, which we can offer you in special materials. The sound generated is emitted via a maximum-sized flat membrane with maximum efficiency into the cleaning medium and targeted at the items to be cleaned.

The LCT plate transducers consist of a straight or offset stainless steel membrane. These are flanged into a corresponding opening in the cleaning tank using a weld-in/pressure frame to save space. Installation does not reduce the existing tank volume. Plate transducers are therefore ideal for the initial fitting and retrofitting of existing baths.

LCT Longlife systems are characterized by a robust design made of duplex stainless steel 1.4462 with a 5mm US diaphragm and a 3mm thick housing. These systems are available in single and dual frequency.

Trial requests

We would be happy to visit you on site with our LCT mobile on wheels to give you a practical demonstration of our products..

You are welcome to send us your soiled or residue-laden production parts and we will find the right cleaner or cleaning process for your application.

In our technical centre, we can simulate all application processes, from simple dipping to spraying to ultrasound or high-pressure processes.

Contact us at any time!

Please fill in the adjacent fields or call us.

E-mail address

info@laue-cleaning-technology.de

Phone | Fax

+49 (0) 5 71 / 38 60 14 99

+49 (0) 5 71 / 38 61 05 05

Address

Lindenstraße 31

DE-32457 Porta Westfalica

Request further information

Please send me further information by e-mail on the following topics: